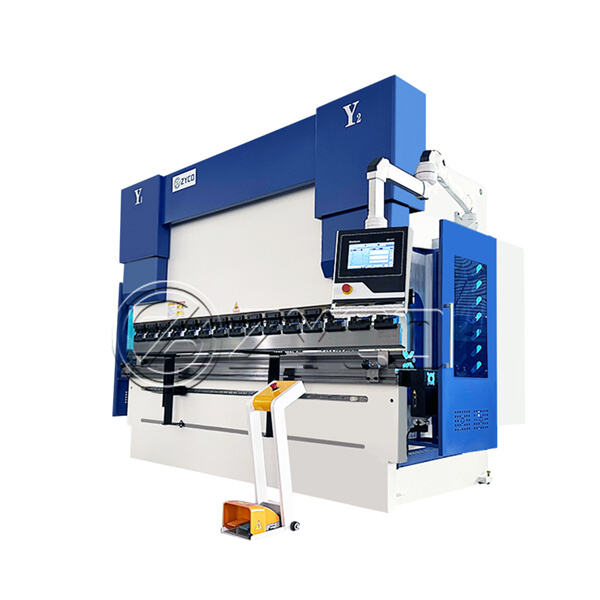

A sheet bending machine is a tool used to flex slim sheets of steel or various other products. It's a device beneficial in producing items like automobile body components, indications, and braces, to few name. The benefits of sheet bending machine over antique bending techniques. ZYCO sheet bending machine is much faster, more accurate, and phone telephone calls for much less labor, rendering it a skilled and service cost-effective companies.

Sheet bending machine have come a lengthy manner in current years, consequently of innovative technologies which have made them more efficient and more simple to run. Some models function automated setups that permit drivers setting the defined easily flex angle and radius. Other individuals use advanced degree sensing units and computer software to exactly determine and change the sheet's place through the process that's bending. These developments have made the ZYCO sheet metal bending equipment more flexible and reliable compared to before.

While modern sheet bending machine have advanced degree safety features, like obstacles and guards to avoid unintentional contact, it's crucial to simply take appropriate precautions when using them. Drivers must constantly wear safety hand wear equipment covers and attention protection, together with follow established safety procedures, like avoiding disruptions and preserving a risk-free range through the ZYCO auto bending machine moving components.

Utilizing a sheet bending machine some essential knowledge and abilities. The driver will need to set the preferred flex angle and radius, load the sheet on the ZYCO steel bending machine. Some devices need the driver to by hand change the sheet's position through the treatment in bending while others use automated manages. The key to success is carefully stay with the manufacturer's instructions and produce a regular and accurate time.

In regards to quality, sheet bending machine is commonly when it come to features, resilience, and satisfaction. It's crucial to select a device that's built to last, with high-quality ZYCO sheet metal bending machine and elements, which will handle the item range that has plenty of thicknesses and products. Furthermore, a manufacturer that's reliable an outstanding performance history of client treatment and support will make all the distinction in regards to having the lots of from the financial investment.

The service team of 20 online employees able to assign engineers the sales team each day. They respond quickly customer queries Sheet bending machine and prepare detailed quotations customers to able to trust. Every customer is dealt with sincerity enthusiasm. You view a video of our factory. If you're planning visit our country, we provide airport pickup well hotel check services.

The frame each machine is created using large-scale processing equipment. This entails processes such heat treatment, general process, sandblasting well as Sheet bending machine. To make frame our equipment more stable durable, and guarantee accuracy of final processing our company has complete production testing system. Our engineers check test the machines continually 24 hours after production of machine is completed. This assures our clients receive item in good working order.

The 20-person online service team assigns engineers sales staff every day, can respond to customer Sheet bending machine timely well as professionally. They also create precise formal quotations. We treat each customer enthusiasm sincerity. Watch short video of our factory. If you come our country, we provide airport pick-up well as hotel check-in services

Our R and D team developed and studied the Sheet bending machine aesthetic components all our mechanical products. For different customers, our R and D team is able assist customers at any time designing machines satisfy their requirements no cost. We will also offer after-sales assistance based upon feedback customers their opinions.

Copyright © NANJING ZYCO CNC MACHINERY CO.,LTD. All Rights Reserved - Privacy policy