- Overview

- Inquiry

- Related Products

The Hydraulic Press Brakes are the tool that is perfect bending and shaping metal sheets with precision and accuracy. These machines that are powerful hydraulic pressure to apply force to metals plates, bending them into the desired shape. The Hydraulic Press Brakes are ideal for use in a variety of industries, including the automotive, aerospace, and construction industries with the ability to bends materials of various thicknesses and sizes.

Certainly one of one of the keys features is the capability to run at high rates, enabling quick and metals that is efficient. The devices include advanced level settings that allows operators to modify the force that is fold angle with simplicity. The settings additionally permits modifications associated with the procedures that is bending making sure the item that is last the specified requirements.

Engineered with durability and security in your minds. The devices are constructed of top-notch materials that can withstand the rigors of constant usage. Furthermore, the devices include higher level security features, including crisis end buttons and security guarding, to guarantee the security of operators.

Designed with ease of use in mind. The machines are intuitive and user-friendly, making them accessible to operators of all skill levels. The Hydraulic Press Brakes can be quickly and easily integrated into existing manufacturing processes with their simple and straightforward designs.

Get your Hydraulic Press Brakes and experienced the power and efficiency of hydraulic metal bending today

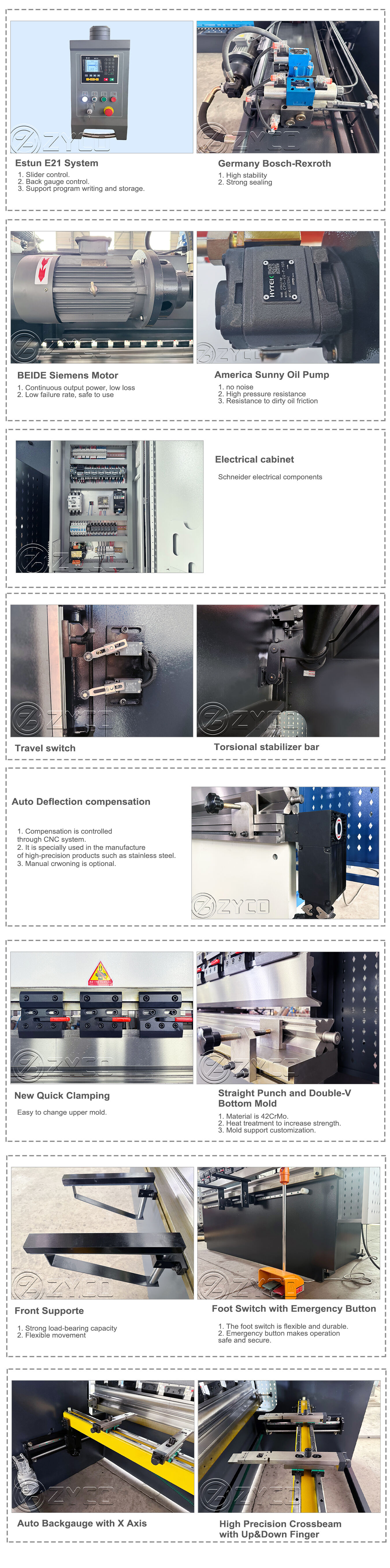

No. |

Component Name |

Brand |

1 |

Controller |

EStun E21 (Optional) Estun, E300P, China (Optional) EYBELEC CT8, Switzerland

|

2 |

Main Motor |

BEIDE Siemens Main Motor |

3 |

Hydraulic system |

UOSHEN, China Taiwan |

4 |

Oil pump |

Sunny, America |

5 |

Electrical components |

Schneider, France |

6 |

Ball screw linear guide rail |

HIWIN, China Taiwan |

7 |

Hydro-cylinder |

Taifen, China Shandong |

8 |

Bear |

NSK, China Shanghai |

This page doesn't support show parameter one by one. If other model, pls consult us. | ||||||

Parameter |

Unit |

Value |

||||

Common Model |

63Tx2500 |

100TX3200 |

160Tx3200 |

200Tx4000 |

||

Pressure |

KN |

630 |

1000 |

1600 |

2000 |

|

Bending Length |

mm |

2500 |

3200 |

3200 |

3200 |

|

Column Distance |

mm |

2030 |

2600 |

2600 |

2600 |

|

Max Opening Height |

mm |

E=440 |

E=480 |

E=500 |

E=520 |

|

Throat Depth |

mm |

D=250 |

D=320 |

D=320 |

D=320 |

|

Slide Stroke(Y-axis) |

mm |

120 |

150 |

200 |

200 |

|

Slide Moving Speed

|

No Loading |

mm/s

|

130 |

|||

Pressing |

12 |

|||||

Returning |

110 |

|||||

Main Motor Power |

KW |

5.5 |

7.5 |

11 |

15 |

|

Machine accuracy

|

Y slider repeat |

mm |

≤±0.02 |

|||

Y slider positioning |

mm |

≤±0.02 |

||||

X, R back gauge repeat positioning |

mm |

≤±0.05 |

||||

Size (L*W*H) |

m |

3 × 1.8 × 2.4 |

3.8 × 1.85 x 2.5 |

3.8 × 1.85 × 2.65 |

3.8 × 1.9 × 2.65 |

|

Weigth |

KG |

5500 |

7500 |

9500 |

12000 |

|

Q: How to get an accurate quotation from us?

A: Please provide us the details of material, max thickness and max width.

Q: Can you do OEM service?

A: Yes, we can. Your design is accepted, your own logo can be used on the machine.

Q: What's the shipping cost from china to your country?

A: We can send machine to your port or door address by sea or airplane.

Please kindly tell us your nearest port or address with postcode.

We have reliable shipping agent to insure the safe convenient and time delivery.

Q: Do you accept LC payment?

A: Yes, normally our payment is 30%+70% T/T, LC payment is also acceptable.

Q: How to operate this machine?

A: Video line of our factory or we send you the video directly.

Q: What about commissioning service?

A: We can offer commissioning service, the buyer need to afford plane tickets.

Q: Do you offer teaching & training?

A: Training at supplier's plant.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY