- Overview

- Inquiry

- Related Products

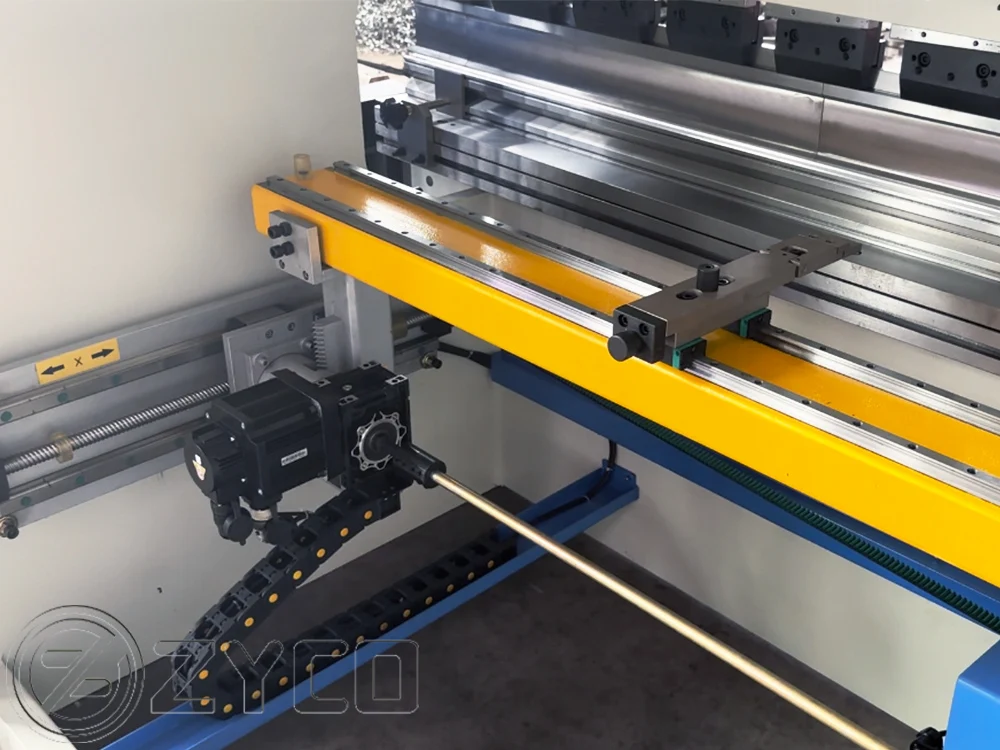

Introducing the Hydraulic Press Brake Machine with TP10S System. This press brake machine is actually a must-have for almost any metalworking establishments that will require high-quality, precision-bending of sheet steel. The TP10S System is a state-of-the-art control system that gives advanced programming capabilities, which makes it simple to create complex, customized bends quickly and effortlessly.

The Hydraulic Press Brake Machine with TP10S System is produced with user-friendly features rendering it a breeze to operate. The apparatus is sold with a display that is built-in is touchscreen provides operators usage of important info such as for instance for circumstances bending angle, straight back gauge place, and allowance that is fold. This product has additionally a simulation that is fold that will help make accuracy that is sure eliminates the requirement for high priced mistake and test.

One of several standout top popular features of the Hydraulic Press Brake Machine with TP10S System is its power to handle a variety this is certainly wide of. The apparatus is designed for steel, aluminum, copper, and steel this is certainly stainless which makes it perfect for use within many industries that are different. Additionally, these devices' hydraulic systems provide constant, uninterrupted power for precise bending even under heavy loads.

The device is designed with sturdy materials, making sure it could withstand use this is certainly heavy perhaps the most applications that are demanding. Furthermore, the machines were created to last, and therefore it shall provide a long period of reliable serviced with just minimal maintenance.

One of the most significant features of this its ease of upkeep. The machine features elements that are easy-to-access making this an easy task to replaced parts when required. Additionally, the device's hydraulic systems are good for easy maintenance, making sure it will continue to run smoothly for decades to the future. Invest into the future from the Hydraulic Press Brake to TP10S System to your metalworking company Machine.

No. |

Component Name |

Brand |

1 |

Controller |

Easycat TP10S (Optional) Estun, E300P, China (Optional) EYBELEC CT8, Switzerland

|

2 |

Main Motor |

BEIDE Siemens Main Motor |

3 |

Hydraulic system |

UOSHEN, China Taiwan |

4 |

Oil pump |

Sunny, America |

5 |

Electrical components |

Schneider, France |

6 |

Servo motor and driver |

Easycat, China |

7 |

Ball screw linear guide rail |

HIWIN, China Taiwan |

8 |

Hydro-cylinder |

Taifen, China Shandong |

9 |

Bear |

NSK, China Shanghai |

This page doesn't support show parameter one by one. If other model, pls consult us. | ||||||

Parameter |

Unit |

Value |

||||

Common Model |

63Tx2500 |

100TX3200 |

160Tx3200 |

200Tx4000 |

||

Pressure |

KN |

630 |

1000 |

1600 |

2000 |

|

Bending Length |

mm |

2500 |

3200 |

3200 |

3200 |

|

Column Distance |

mm |

2030 |

2600 |

2600 |

2600 |

|

Max Opening Height |

mm |

E=440 |

E=480 |

E=500 |

E=520 |

|

Throat Depth |

mm |

D=250 |

D=320 |

D=320 |

D=320 |

|

Slide Stroke(Y-axis) |

mm |

120 |

150 |

200 |

200 |

|

Slide Moving Speed

|

No Loading |

mm/s

|

130 |

|||

Pressing |

12 |

|||||

Returning |

110 |

|||||

Main Motor Power |

KW |

5.5 |

7.5 |

11 |

15 |

|

Machine accuracy

|

Y slider repeat |

mm |

≤±0.02 |

|||

Y slider positioning |

mm |

≤±0.02 |

||||

X, R back gauge repeat positioning |

mm |

≤±0.05 |

||||

Size (L*W*H) |

m |

3 × 1.8 × 2.4 |

3.8 × 1.85 x 2.5 |

3.8 × 1.85 × 2.65 |

3.8 × 1.9 × 2.65 |

|

Weigth |

KG |

5500 |

7500 |

9500 |

12000 |

|

Q:Can you do OEM service?

A:Yes, we can. your design is accepted, your own logo can be used on the machine.

Q:What's the shipping cost from china to your country?

A:We can send machine to your port or door address by sea or airplane.

Q:Do you accept LC payment?

A:Yes, normally our payment is 30%+70% T/T ,LC payment is also acceptable.

Q:How to operate this machine?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service?

A:We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training?

A:Training at supplier's plant

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY