Metal Master Press Brake used to fold metal sheets into desired forms or perspectives. This Metal Master Press Brake, the same as ZYCO's press brake machines forming several benefits which make it better over other machines. One of the obvious features of a Metal Master Press Brake is its level is nearly all of. This Metal Master Press Brake can create accurate and outcomes which can be consistent regardless of the depth or style of steel utilized. Another advantage associated with device is its versatility. The press brake may be employed to create forms which are various bins, perspectives, and curves.

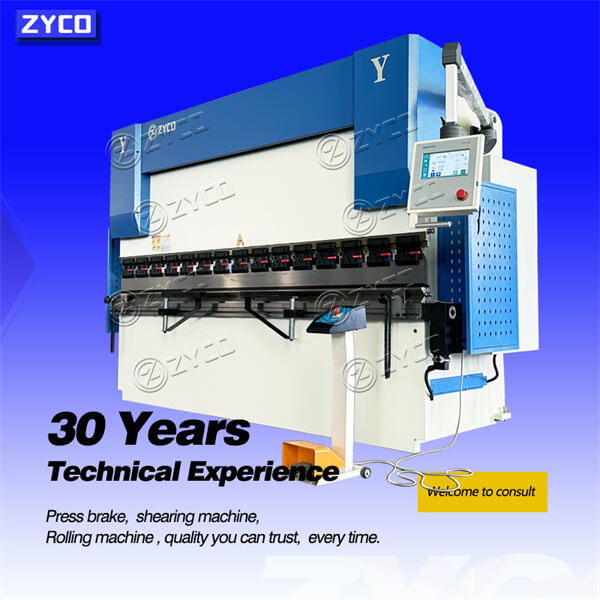

Innovation has been significant inside the development of the Metal Master Press Brake, also the ZYCO's product such as cnc press brake. Among the main innovations in the past few years will be the incorporation of computer numeric control. The technology uses computers to modify the motion in connection with steel bending machine. This innovation has generated consistent and results being precise have increased the speed and effectiveness of manufacturing.

Safety is paramount whenever managing any equipment, and the Metal Master Press Brake, similar to the hydraulic press brake innovated by ZYCO isn't any exception. This machine has safety is various set up to market safe operations. One of the main safety features could be the crisis end switch. The operator can press the emergency stop change to get rid of the equipment instantly just in case there is a major accident or danger. The device comes with security guards that protect the operator through the components being moving. Also, the equipment's control system monitors the pressure and heat, and the device prevents automatically as soon as the limits are exceeded.

Using a metal master press brake, along with ZYCO's product cnc press brake machine is straightforward and simple. The initial step would be to organize the steel sheet by cleaning it and marking the bending career . The metal sheet is then placed on the sleep bending additionally the clamp holds it set up. The operator sets the desired angle and depth making use of the CNC control system. The product then bends the steel sheet into the desired form. The steel sheet is removed from the bending bed, as well as the last product is examined to make certain it fulfills the necessary requirements after the process.

Quality is simply an aspect is crucial of device, including the Metal Master Press Brake, identical to hydraulic press brake machine supplied by ZYCO. This product is manufactured out of high-quality materials that ensure its durability. More over, the incorporation of CNC technology has enhanced the machine's accuracy, rate, and effectiveness. This innovation has additionally paid down mistake which regularly contributes to inconsistencies and additional expenses. Finally, in the event the equipment experiences a quality issue technical can be had to solve it quickly and effectively.

Our 20-person team of online service, which allocates engineers every day the sales team, can respond quickly efficiently customer requests offer exact complete quotations. Every customer dealt with genuine and enthusiastic manner. You can watch video our Metal master press brake. We offer airport pickup hotel check-in when visit our country.

We have entire R and D and design team has thoroughly analyzed and designed appearance electronic components our mechanical products. Our R and D team available help customers anytime online designing machines that meet requirements their particular needs. After-sales, we will also offer customer feedback opinions, Metal master press brake improvements innovation are made make equipment more affluent with latest aesthetics, to more effectively assist customers manufacturing processing.

The frame each machine manufactured through large-scale processing equipment, which involves processes like heat treatment, overall processing, sandblasting, welding. To make frame our equipment more durable Metal master press brake, and ensure accuracy the final production process we use full manufacturing testing process. Our engineers examine test machines continuously a period of 24 hours after production of machine has been completed. This ensures that client receives an equipment in good shape.

Our team of Metal master press brake from online service, which allocates engineers daily our sales team, able to respond quickly efficiently customer requests offer precise and accurate quotes. Every customer treated with passion and sincerity. You can view video our manufacturing facility. If you come our country, we will provide airport pick-up hotel check-in services

Copyright © NANJING ZYCO CNC MACHINERY CO.,LTD. All Rights Reserved - Privacy policy