- Overview

- Inquiry

- Related Products

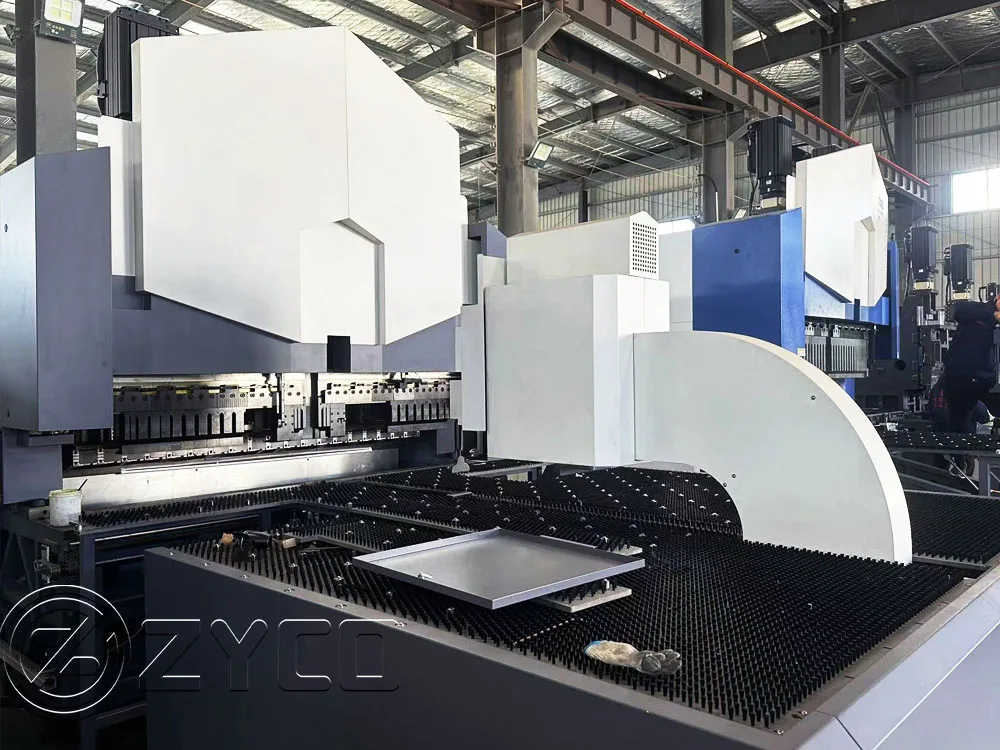

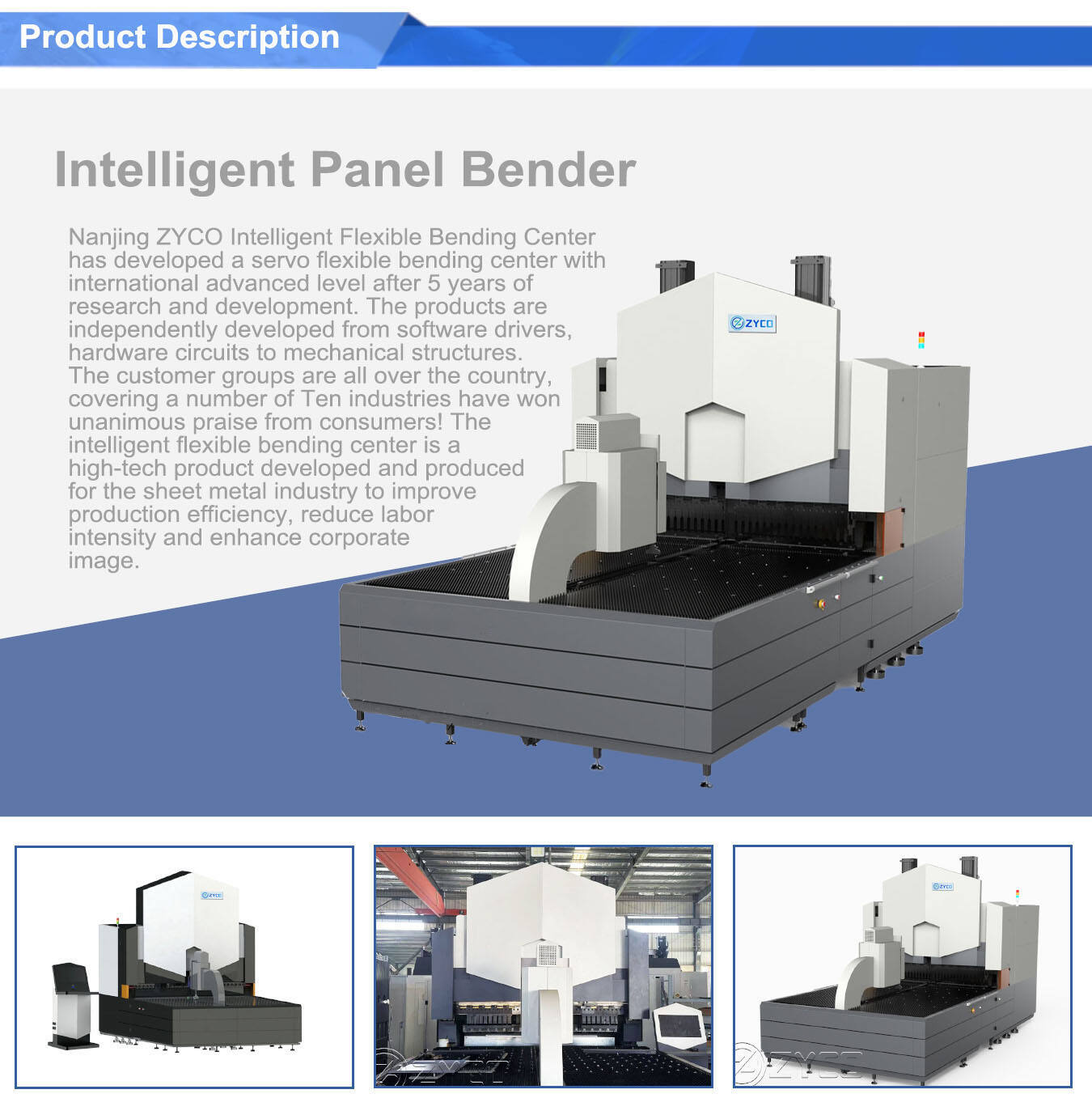

ZYCO's Industrial Automatic Intelligent Panel Metal Bending Center is a effective and machine that is efficient is industrial is built to help organizations optimize their efficiency. This device is ideal for any ongoing business that should fold metal panels quickly and accurately.

On the list of key attributes of the Industrial automated smart Panel Metal Bending Center is its programming that is automated system. This method enables these devices to be programmed with certain habits that are bending that can easily be duplicated with great precision. This feature that is particular that every panel is bent for your requirements being exact, meaning that businesses can save time and money by perhaps not having to manually adjust the equipment.

The unit may be built with a control that is intelligent that will help so that the entire process is streamlined. This technique provides feedback that is real-time their state when it comes to device, including info on the bending angle, force, and speed. This means operators can quickly determine any problems and also adjust as needed, that will help reduce downtime while increasing productivity.

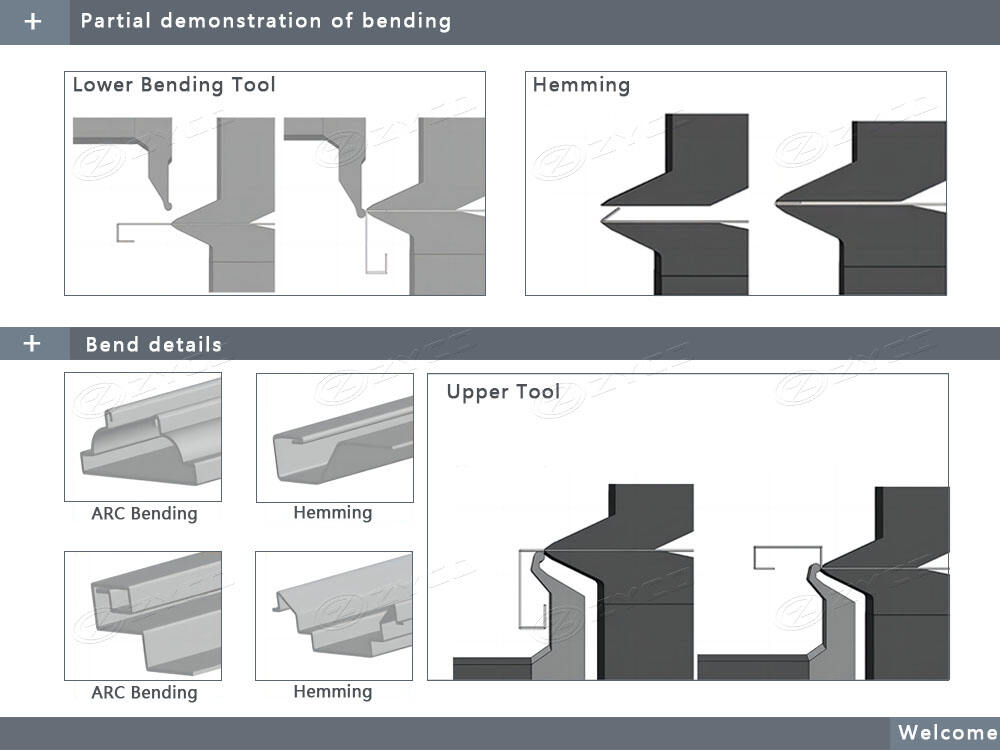

In addition, the Industrial automated smart Panel Metal Bending Center has a high-precision servo motor system that ensures bending that is accurate positioning. The device has the capacity to adjust the angle this is certainly bending place of the steel panel with amazing precision, which means companies can create top-notch finished items each and every time.

The device normally made for simplicity of use. It comes having a course this is certainly allows that are user-friendly to easily and quickly program the equipment. The product may be built to be easy to maintain, meaning organizations can efficiently ensure that it stays operating with reduced effort.

| No. | Component Name | Details |

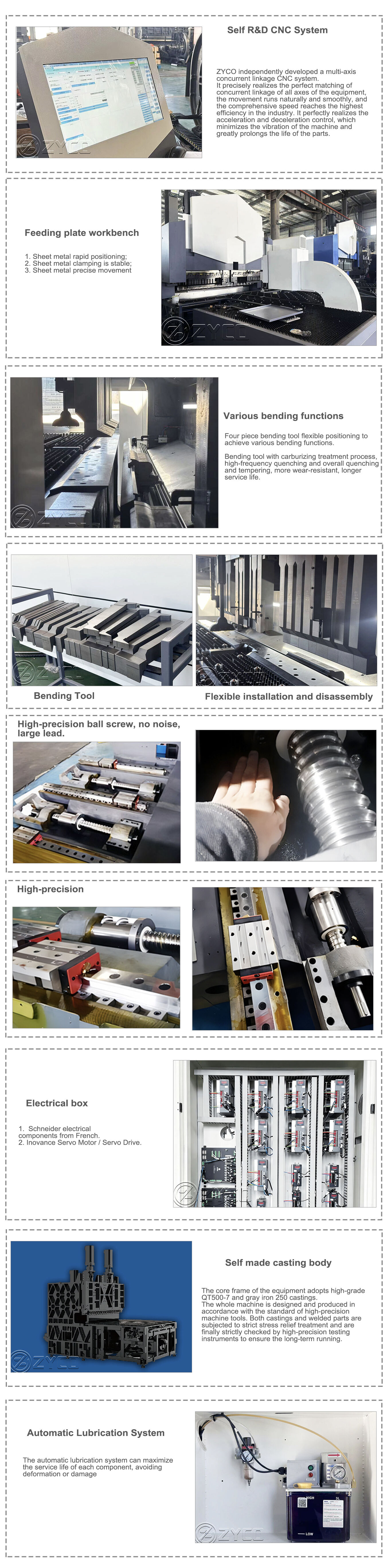

| 1 | Control system | Self R&D |

| 2 | Servo Motor / Servo Drive | Inovance, China |

| 3 | Ball screw / linear guide rail | HIWIN, Taiwan |

| 4 | Bearing | NACHI, Japan |

| 5 | Lathe bed | Self made casting body |

| 6 | Bending Tool | Self R&D |

| 7 | Reducer | China |

| 8 | Electrical components | Schneider, French |

| 9 | Oil system | Yuxiang, Taiwan |

| No. | Model | 1400P | 2500P |

| 1 | Minimum bending accuracy | 0.001 mm | 0.001 mm |

| 2 | Max bending speed | 0.2 second/time | 0.2 second/time |

| 3 | Max feeding speed | 90 m/min | 90 m/min |

| 4 | Max.bending width | 1400 mm | 1400 mm |

| 5 | Max.Bending size | L 1400mm -- W 1400mm | L 1400mm -- W 1400mm |

| 6 | Max. Bending height | 170mm | 170mm |

| 7 | Min. Bending height | 3mm | 3mm |

| 8 | Min.arc radius | 0.5mm | 0.5mm |

| 9 | User operating environment | Win7 or above system | Win7 or above system |

| 10 | Max. Bending thickness | stainless steel 1.5mm Cold panel 2.0 mm Aluminum panel 3.0mm | stainless steel 1.5mmCold panel 2.0 mm Aluminum panel 3.0mm |

| 11 | Min. Bending thickness | 0.35mm | 0.35mm |

| 11 | Four side forming min. Inner size | 140mmx190mm | 140mmx190mm |

| 12 | Double side forming min. Inner size | 140mm | 140mm |

| 13 | Bending angle | 0-180 degree | 0-180 degree |

| 14 | Axis | 15 | 15 |

| 15 | Motor power | 40KW | 79 KW |

| 16 | Average power | 1.9KW | 2.9 KW |

| 17 | Machine size | 4400x1900x2900 mm | 5650x3000x3400 mm |

| 18 | Total weight | 12000 KG | 19000 KG |

| 19 | Rated power | 380V 3Phase 50Hz | 380V 3Phase 50Hz |

Q:How to get an accurate quotation from us?

A:Please provide us the details of material, max thickness and max width.

Q:Can you do OEM service?

A:Yes, we can. your design is accepted, your own logo can be used on the machine.

Q:What's the shipping cost from china to your country?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment?

A:Yes, normally our payment is 30%+70% T/T, LC payment is also acceptable.

Q:How to operate this machine?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service?

A:We can offer commissioning service; the buyer needs to afford plane tickets.

Q:Do you offer teaching & training?

A:Training at supplier's plant.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY