Omfattande guide till bockningsformning

Vad bildas böjning?

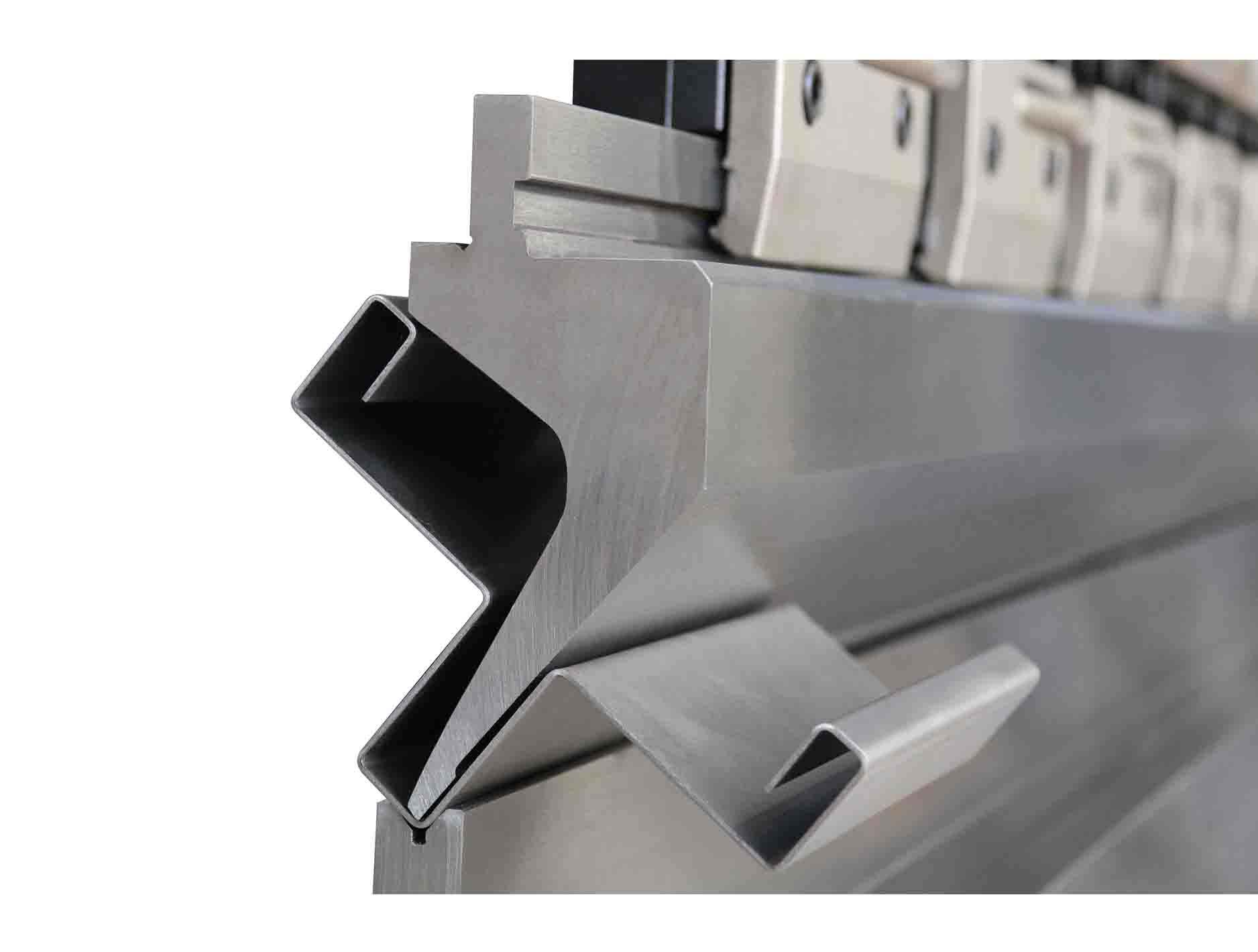

Böjformning är en formningsteknik som ofta används inom metallbearbetning. Det används mest inom plåtbearbetningsindustrin. Allmänna maskiner är i allmänhet kantpressar och plåtvalsmaskiner. Den applicerar extern kraft på metallplåten för att få den att plastiskt deformeras och därigenom erhålla önskad form och storlek. Jämfört med andra formningsprocesser har denna metod fördelarna med enkel drift, låg investering och stabil produktkvalitet. Det används ofta inom maskintillverkning, byggnadsdekoration, elektroniska apparater och andra industrier.

Grundläggande principer för böjformning

Kärnan i böjformningen är att utnyttja de plastiska deformationsegenskaperna hos metallplåtar. När belastningskraften är större än metallmaterialets sträckgräns kommer materialet att genomgå plastisk deformation, vilket ger den önskade böjformen. Många faktorer måste beaktas i denna process, såsom materialtjocklek, böjradie, fixturdesign, etc., för att säkerställa den slutliga produktens dimensionella noggrannhet och utseendekvalitet.

Vanliga bockningsmetoder

1. Manuell bockning: Använd handverktyg som tång och hammare för att utföra enkel bockningsbearbetning på små plåtbitar. Lämplig för formning av små partier och enkla komponenter.

2. Mekanisk bockning: Böjning görs med specialutrustning såsom kantpressar och hydrauliska pressar. Den kan realisera bildandet av stora mängder komplexa komponenter och är lämplig för standardiserad produktion.

3. Rullböjning: Använd ett eller flera par formningsrullar för att kontinuerligt rulla och böja metallplåtar. Den är lämplig för att forma komponenter med längre längder och mindre böjningsvinklar.

4. CNC-böjning: Använd CNC-teknik på bockningsbearbetning och slutför den automatiserade formningen av komplexa komponenter genom programstyrning. Det kan uppnå hög precision och högeffektiv böjningsbearbetning.

Försiktighetsåtgärder för böjning och formning

I praktiska tillämpningar är det nödvändigt att fullt ut överväga faktorer som metallmaterialegenskaper, processparametrar och fixturdesign för att säkerställa böjkvalitet. Till exempel kan en lämplig böjningsradie undvika materialbrott, en rimlig böjvinkel kan bidra till att förbättra dimensionsnoggrannheten och rimliga processparametrar kan hjälpa till att förbättra produktionseffektiviteten. Samtidigt bör uppmärksamhet ägnas åt arbetsstyckets ytkvalitet och spänningstillstånd för att uppfylla kraven för användning.

Kort sagt, bockning och formning är en enkel och effektiv metallbearbetningsmetod som används flitigt i många industrier. Genom att behärska de grundläggande principerna och vanliga processerna för bockning och formning kan metallbearbetningsföretag kontinuerligt förbättra produktkvaliteten och produktionseffektiviteten för att möta marknadens efterfrågan.

Rekommenderade produkter

Heta nyheter

-

Saudiarabien-WC67K 100T 3200 NC kantpress & QC12K-4x3200 klippmaskin & 3x3100 vikmaskin

2024-11-11

-

USA-PANEL 1400PA3-DA BÖCKCENTER

2024-10-28

-

Argentina-WC67K 125T 3200 CNC kantpress & QC12K-4X3200 klippmaskin

2024-10-25

-

Huvudsakliga användningsområden och utveckling av bockningscenter

2024-10-24

-

Indonesien-WC67K-30T 1600/63T 2500/100T3200/160T 3200 CNC kantpress

2024-10-21

-

Hur man hanterar bristen på tryck i kantpressen

2024-10-15

-

Så här underhåller du en kantpress: 28 tips för att hålla kantpressen i perfekt skick

2024-10-04

-

Mexiko WC67K 80T 3200 NC kantpress & QC12k-6×3200 klippmaskin

2024-09-26

-

Omfattande guide till bockningsformning

2024-09-26

-

Välkommen indiska kunder att besöka vår fabrik

2024-09-23

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY