3. En dıştaki sabit kalıplı tahta sandıktır.

4. Tahta kasanın alt kısmı, teslim edilmesi ve taşınması kolay, sağlam bir demir krikoya sahiptir.

eksenler |

X1(X) |

X2 |

R1(R) |

R2 |

Z1 |

Z2 |

Strok (mm) |

750 |

750 |

150 |

150 |

/ |

/ |

Hız(mm/sn) |

500 |

500 |

180 |

180 |

2000 |

2000 |

Doğruluk (mm) |

0.02 |

0.02 |

0.05 |

0.05 |

0.05 |

0.05 |

Motor |

servo motor |

servo motor |

servo motor |

servo motor |

servo motor |

servo motor |

Mekanik sistem |

vidalı |

vidalı |

raf |

raf |

raf |

raf |

Zyco dünyaca ünlü bir sac ekipman üreticisidir. "Zyco" markası uluslararası sac ekipmanları alanında lider bir marka olup uzun yıllara dayanan bir markadır. Grup kendini ürünlerin geliştirilmesine, üretimine ve pazarlanmasına adamıştır. Şirketin ana ürünleri şunlardır: CNC bükme makinesi, kesme makinesi, hidrolik pres, lazer kesme makinesi, CNC levha haddeleme makinesi ve diğer sac işleme ekipmanları. Avrupa Belçika dövme takım tezgahı üretim teknolojisini kullanıyoruz. Avrupa, Amerika, Orta Doğu, Güney Afrika, Güneydoğu Asya ve 30'dan fazla ülke ve bölgeye ihraç edilmektedir. Dünya standartlarında tasarım ve üretim yeteneklerine sahip profesyonel bir Ar-Ge ekibimiz var.

A: Tedarikçinin fabrikasında eğitim

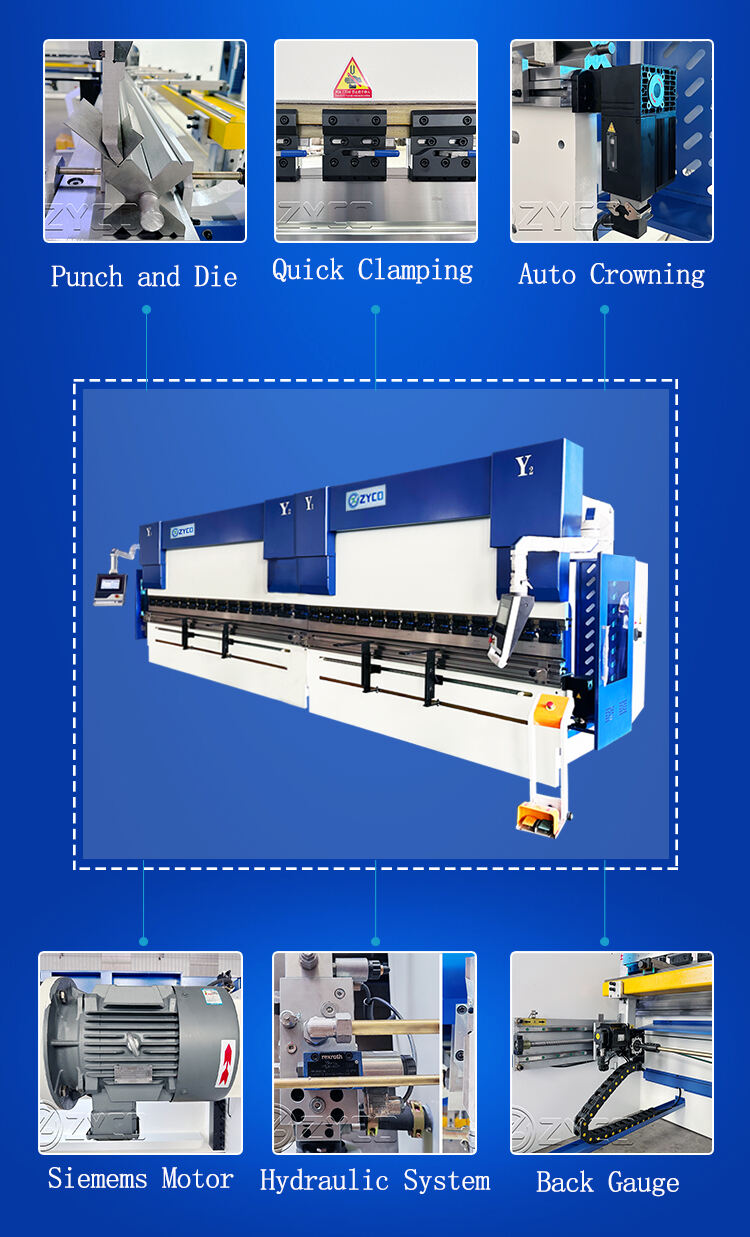

ZYCO tandem abkant abkant bükme makineleri, daha yüksek üretim gereksinimlerini karşılamak ve yüksek kalitede verimlilik sağlamak için geliştirilmiştir. Kendine has dayanıklı yapısı ve dahiyane fonksiyonlarıyla bu makine, optimum doğruluğu ve güvenilirliği garanti ederek, yüksek hacimli sabit sonuçlara ve üretime ihtiyaç duyan şirketler için uygun bir seçenek haline getiriyor.

En kaliteli ürünler kullanılarak üretilen ve inovasyon, her biri verimli ve dayanıklı olan bir ürüne doğru öne çıkıyor. Kullanıcı dostu olan kendi yönetimi, sürücünün makineyi zor görevlerde olduğu gibi basit bir şekilde hızlı bir şekilde çalıştırabilmesini sağlar. Tandem tarzı, aynı anda 2 esnekliğin oluşturulmasına izin vererek üretim yeteneğinden en iyi şekilde yararlanır, bu da fırsat ve etkinliği korur.

Komut, bu özel abkant presin tandemi olup konfigürasyonu azaltır ve verimlilikten ve fırsatlardan en iyi şekilde yararlanır. Gelişmiş program gövdesi, en çok ihtiyaç duyulan görevler için hassas doğruluk ve tekrarlanabilirlik sunar. Makinenin gelişmiş performansı, en karmaşık bükme taleplerini basit bir şekilde karşılamasını sağlar. ZYCO tandem abkant abkant bükme makinesi, müşterinin daha yüksek miktardaki ürünü veya hatta muhtemelen özelleştirilmiş bir görevi ele almasına bakılmaksızın, yüksek düzeyde birinci sınıf verimliliği garanti eder.

Azaltılmış bakım gereksinimleriyle çalışacak şekilde tasarlanan bu abkant pres makinesinin çalıştırılması kolaydır ve arıza süresini en aza indiren optimum sonuç sunar. ZYCO pres durdurma gövdesi, iki bilgiden daha yüksek bir seviyeye sahip olacak şekilde hazırlanmış ve üretilmiştir, her seferinde hassas ve sabit bükme sonuçları sağlamasını garanti eder.

Bu özel öğenin bir başka öne çıkan özelliği de kendi güvenlik önleyici tedbirleridir. Güvenlik ortamının ilerletilmesiyle sürücüler, öz güvenlik ve gönül rahatlığıyla görev yapabilirler. Güvenlik fonksiyonları bir lazer cihazı güvenlik gövdesinden, kilitlerden ve ayrıca otomatikleştirilmiş bir cihaz kelepçe gövdesinden oluşur.

Esneklik söz konusu olduğunda kapsamlı bir ürün ve talep yelpazesini ele alma becerisine sahiptir. ZYCO tandem abkant pres makinesi, plastik ürünlerin yanı sıra paslanmaz, hafif alüminyum ve metalden oluşan ürün yelpazesinde sürekli verimliliği artırıyor.

ZYCO tandem abkant abkant bükme makinesi, benzersiz hassasiyet, esneklik ve güvenilirlik sağlayan yüksek performanslı bir üründür. Kendi birleşik komuta yapısı, gelişmiş program gövdesi, basit prosedür ve güvenlik işlevleriyle bu makine, yüksek premium sonuçlara ihtiyaç duyan her tür şirket için akıllıca bir finansal varlıktır. Optimum etkinlik, verimlilik ve hassasiyet için ZYCO tandem abkant abkant bükme makinesini seçin.

Telif Hakkı © NANJING ZYCO CNC MACHINERY CO.,LTD. Tüm Hakları Saklıdır - Gizlilik Politikası