3. The outmost is wooden case with fixed formwork.

4. Thebottom of the wooden case has firm iron jack, convenient to handing and transport

Type | Nominal pressure | Working table and tooling length | Center distance between uprights | Throat Depth | Ram stroke | Max Open | Main motorpower | Dimension |

(KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (KW) | L*W*H(mm) | |

80/20 | 800 | 2000 | 1550 | 400 | 200 | 400 | 7.5 | 2100*1750*2900 |

80/25 | 800 | 2500 | 2050 | 400 | 200 | 400 | 7.5 | 2600*1750*2900 |

80/32 | 800 | 3200 | 2600 | 400 | 200 | 400 | 7.5 | 3500*1750*2900 |

100/25 | 1000 | 2500 | 2050 | 400 | 200 | 400 | 7.5 | 2600*1750*2900 |

100/32 | 1000 | 3200 | 2600 | 400 | 200 | 400 | 7.5 | 3500*1750*2900 |

100/40 | 1000 | 4000 | 3550 | 400 | 200 | 400 | 7.5 | 4500*1700*3100 |

135/32 | 1350 | 3200 | 2600 | 400 | 200 | 400 | 7.5 | 3500*1700*3100 |

135/40 | 1350 | 4000 | 3150 | 400 | 200 | 400 | 7.5 | 4500*1700*3100 |

160/32 | 1600 | 3200 | 2600 | 400 | 200 | 400 | 11 | 3500*1700*3100 |

160/40 | 1600 | 4000 | 3150 | 400 | 200 | 400 | 11 | 4500*1700*3100 |

200/32 | 2000 | 3200 | 2600 | 400 | 250 | 485 | 15 | 3500*1900*3200 |

200/40 | 2000 | 4000 | 3150 | 400 | 250 | 485 | 15 | 4300*1900*3200 |

250/32 | 2500 | 3200 | 2600 | 400 | 250 | 485 | 15 | 3500*2100*5300 |

250/40 | 2500 | 4000 | 3150 | 400 | 250 | 485 | 15 | 4300*1900*3200 |

250/60 | 2500 | 6000 | 5050 | 400 | 250 | 485 | 15 | 6600*2100*3500 |

320/40 | 3200 | 4000 | 3150 | 400 | 250 | 570 | 22 | 4600*2200*3500 |

320/60 | 3200 | 6000 | 5050 | 400 | 250 | 570 | 22 | 6600*2200*3600 |

400/40 | 4000 | 4000 | 3450 | 400 | 300 | 570 | 37 | 5000*3600*5200 |

400/50 | 4000 | 5000 | 4050 | 400 | 300 | 570 | 37 | 6000*3600*5500 |

400/60 | 4000 | 6000 | 5050 | 400 | 300 | 570 | 37 | 7000*3650*5750 |

500/40 | 5000 | 4000 | 3150 | 400 | 300 | 600 | 45 | 5000*3650*6100 |

500/50 | 5000 | 5000 | 4050 | 400 | 300 | 600 | 45 | 5000*1950*3000 |

500/60 | 5000 | 6000 | 5050 | 400 | 300 | 600 | 45 | 7000*3650*5850 |

640/60 | 6400 | 6000 | 5050 | 400 | 320 | 640 | 55 | 7000*3610*5900 |

640/70 | 6400 | 7000 | 6050 | 400 | 320 | 640 | 55 | 8000*3800*6100 |

640/80 | 6400 | 8000 | 6200 | 400 | 320 | 640 | 55 | 8010*3900*6150 |

800/60 | 8000 | 6000 | 4760 | 500 | 400 | 820 | 2*37 | 7000*4000*6150 |

800/70 | 8000 | 7000 | 5760 | 500 | 400 | 820 | 2*37 | 8000*4000*4200 |

800/80 | 8000 | 8000 | 6200 | 500 | 400 | 820 | 2*37 | 8050*4100*6200 |

Zyco is a world famous manufacturer of sheet metal equipment. Its "Zyco" brand has been a leader In the international field of sheet metal equipment has many years of brand. The Group is committed to the development, production and marketing of products. The company's main products are: CNC bending machine, shearing machine, hydraulic press, laser cutting machine, CNC plate rolling machine and other sheet metal processing equipment. We use the European Belgium forging machine tool production technology. Exported to Europe, America, the Middle East, South Africa, Southeast Asia and more than 30 countries and regions. We have a professional R & D team with world-class design and manufacturing capabilities

A: Training at supplier's plant

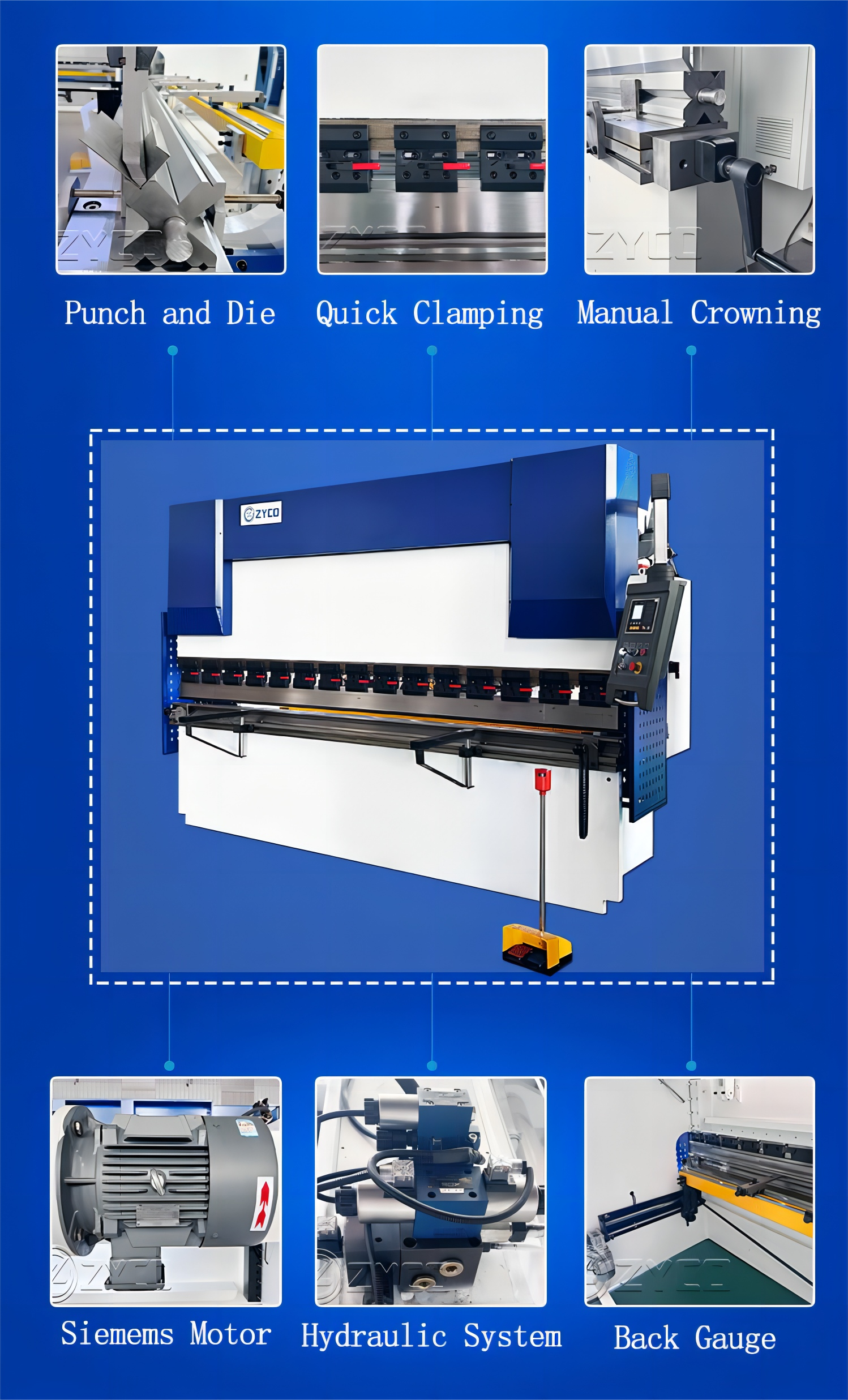

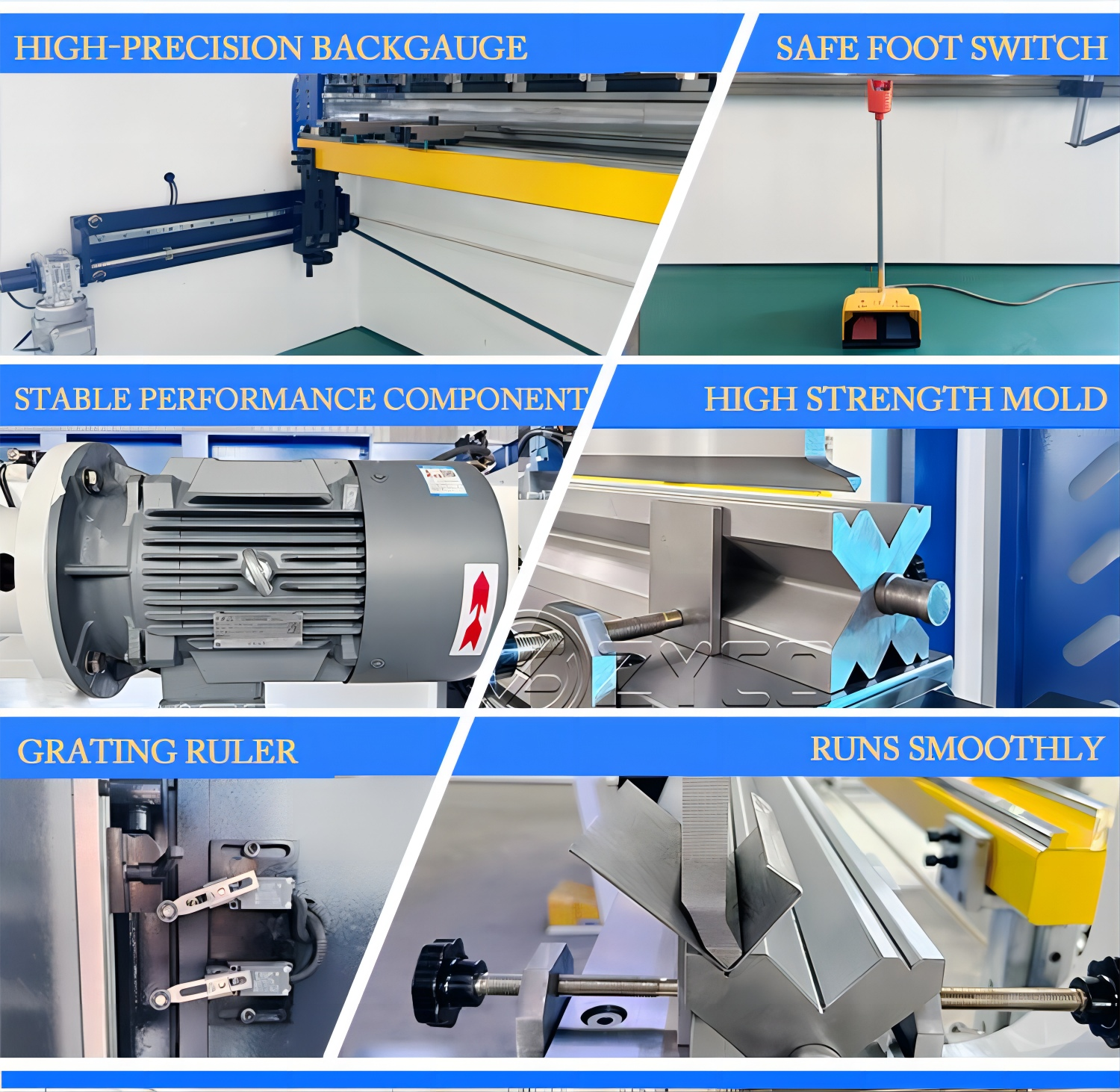

Presenting the popular CE torsion axis servo CNC press brake with TP-10S bodies coming from the widely known brand name ZYCO, a hydraulic press-brake pads making machine that is developed to create your press brake procedures much a lot extra precise and effective.

Functions a torsion axis servo electric motor that provides higher accuracy and efficiency is soft. The electric motor is servo the equipment's precision throughout the bending procedure through managing the location of this particular bending beam of light and the rear evaluate precisely. Which implies the gadget can deal constant and bending is precise despite the intricacy of the flexes.

Likewise equipped with a TP-10S body that improves the machine's versatility. The body allows the driver to course several flexes in a manufacturing operate is solitary. Furthermore, it provides info is outlined the bending procedure, like for instance the flex slants and likewise the variety of flexes created. The TP-10S body likewise creates advancement and changing the devices easy and fast.

Produced utilizing high-quality products that guarantee its own durability and resilience. The machine was produced to endure the roughness of a manufacturing is hectic and provides hassle-free efficiency for years to happened. The machine is likewise simple to preserve, lots of thank you to its own easy style and user interface is easy to use.

Functions a user interface is easy to use creates it simple for the driver to utilize the gadget. The setups are easy and user-friendly to comprehend, enabling also beginner individuals to run the devices with simplicity. Additionally, the machine is geared up with safety functions that guarantee the operator's safety when utilizing the machine.

The CNC press brake's pad-making abilities are another include that creates it be discovered coming from its own rivals. The devices can create press is first-class pads of various dimensions and forms. The machine's ability to create particular and press is custom-designed pads provides it a side over various other press brake devices in the market.

The ZYCO CE torsion axis servo CNC press brake with TP-10S body is a flexible, dependable, and effective machine that will transform your press brake procedures. Its own progressed functions, resilience, and user-friendliness create it an outstanding financial asset for any type of production company that needs precisions, precision, and effectiveness in its own bending procedures.

Copyright © NANJING ZYCO CNC MACHINERY CO.,LTD. All Rights Reserved - Privacy policy