3. The outmost is wooden case with fixed formwork.

4. Thebottom of the wooden case has firm iron jack, convenient to handing and transport

This page doesn't support show parameter one by one. If other model, pls consult us. | |||||||

Parameter | Unit | Value | |||||

Common Model | 63Tx2500 | 100TX3200 | 160Tx3200 | 200Tx4000 | |||

Pressure | KN | 630 | 1000 | 1600 | 2000 | ||

Bending Length | mm | 2500 | 3200 | 3200 | 3200 | ||

Column Distance | mm | 2030 | 2600 | 2600 | 2600 | ||

Max Opening Height | mm | E=440 | E=480 | E=500 | E=520 | ||

Throat Depth | mm | D=250 | D=320 | D=320 | D=320 | ||

Slide Stroke(Y-axis) | mm | 170 | 200 | 200 | 220 | ||

Slide Moving Speed | No Loading | mm/s | 200 | ||||

Pressing | 12 | ||||||

Returning | 170 | ||||||

Main Motor Power | KW | 5.5 | 7.5 | 11 | 15 | ||

Machine accuracy | Y slider repeat | mm | ≤±0.02 | ||||

Y slider positioning | mm | ≤±0.02 | |||||

X, R back gauge repeat positioning | mm | ≤±0.05 | |||||

Size (L*W*H) | m | 3 × 1.8 × 2.5 | 3.8 × 1.85 x 2.6 | 3.8 × 1.85 × 2.65 | 3.8 × 1.9 × 2.65 | ||

Weigth | KG | 5500 | 7500 | 9500 | 12000 | ||

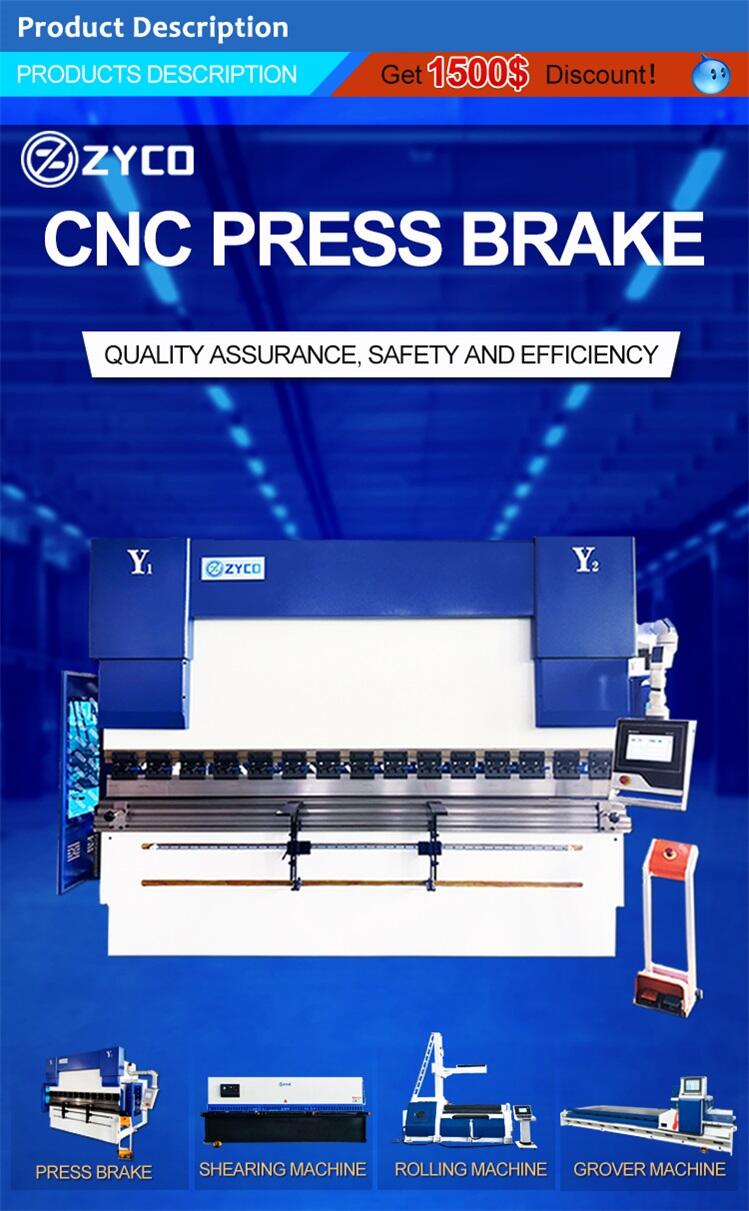

Zyco is a world famous manufacturer of sheet metal equipment. Its "Zyco" brand has been a leader In the international field of sheet metal equipment has many years of brand. The Group is committed to the development, production and marketing of products. The company's main products are: CNC bending machine, shearing machine, hydraulic press, laser cutting machine, CNC plate rolling machine and other sheet metal processing equipment. We use the European Belgium forging machine tool production technology. Exported to Europe, America, the Middle East, South Africa, Southeast Asia and more than 30 countries and regions. We have a professional R & D team with world-class design and manufacturing capabilities

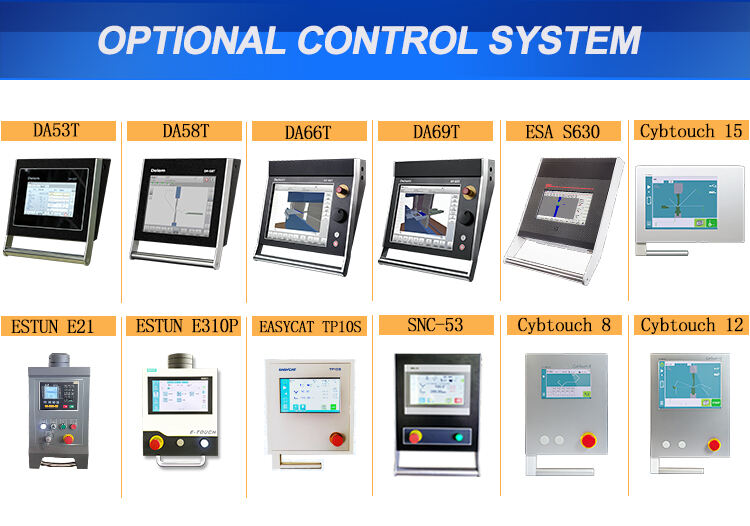

The DA53T electro-hydraulic bending machine is an advanced CNC equipment that is widely used in various metal processing industries.

1. Main features:

1.1 High-precision control: The DA53T electro-hydraulic Press Brake adopts an advanced CNC system. Through precise parameter setting and real-time monitoring, it can ensure the accuracy of the angle and position of each bending is consistent.

1. 2 Powerful bending ability: This equipment has a large bending force and bending length range. Whether it is a thin plate or a thick plate, the DA53T electro-hydraulic bending machine can complete the bending task stably and efficiently.

1.3 Flexible operation interface: The DA53T electro-hydraulic bending machine is easy to operate and equipped with an intuitive and friendly human-machine interface. At the same time, the device supports multiple languages to facilitate international applications.

1.4 Safe and reliable: DA53T electro-hydraulic bending machine has a complete safety protection system, including photoelectric fence, emergency stop button, etc.

2. Advantages:

2.1 Efficient production: It has the characteristics of quick response and high-speed movement, which can improve daily production efficiency.

2.2 High accuracy: This equipment adopts a closed-loop control system, which can monitor the parameters in the bending process in real time. If there are errors, they can be adjusted in time to ensure the accuracy of the bending angle and position.

2.3 Multi-functional application: The DA53T electro-hydraulic bending machine is suitable for processing workpieces of various shapes and sizes. Different basic bending machines can be customized according to different needs to meet the processing needs of different workpieces.

3. Application fields:

DA53T electro-hydraulic bending machine is widely used in the metal processing industry, especially suitable for the following fields:

3.1 Metallurgical industry 3.2 Automobile manufacturing 3.3 Medical device industry

3.4 Construction industry 3.5 Aerospace 3.6 Kitchenware industry.

in conclusion:

The DA53T electro-hydraulic bending machine has become one of the indispensable equipment in the metal processing industry with its efficient and precise bending capabilities. With the advent of the Industry 4.0 era, the DA53T electro-hydraulic bending machine will continue to evolve, bringing more innovation and convenience to the metal processing industry.

Copyright © NANJING ZYCO CNC MACHINERY CO.,LTD. All Rights Reserved - Privacy policy