Meriv çawa pirsgirêka zextê li ser makîneya benderê çareser dike

Makîneyên qutkirinê makîneyên herî berbelav ên di pîşesaziya metalê de ne. Di dema karanîna demdirêj de, dibe ku makîneyê zextê neke. Di vê gotarê de, em ê sedem û çareseriyên van pirsgirêkan ji we re analîz bikin.

1. Pirsgirêkên pergala hîdroulîk

(1) Kêmasiya rûnê hîdrolîk an jî kalîteya neftê ya nebaş.

Pergala hîdrolîk pêdivî bi rûnê hîdrolîk têr heye ku bi rêkûpêk bixebite. Ger rûnê hîdrolîk pir hindik be an jî qalîteya rûnê xizan be, ew ê bandorê li xebata normal a pergalê bike û bibe sedema ku makîneya guheztinê têk neçe. Di wextê de asta rûnê hîdrolîk û kalîteya rûnê kontrol bikin, û di wextê de rûnê hîdrolîk lê zêde bikin an biguhezînin.

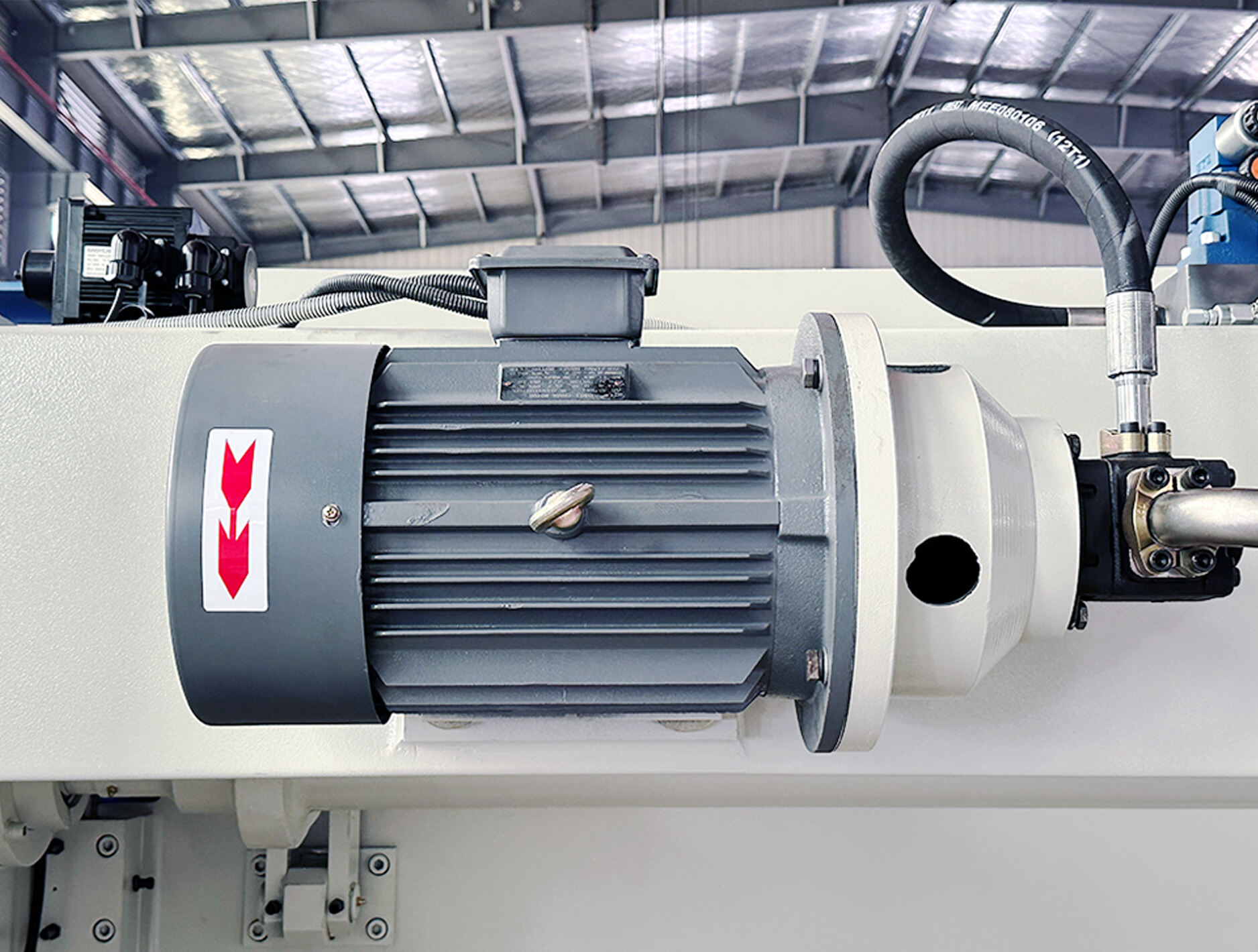

(2) Pompeya rûnê têk diçe. Pompeya rûnê hêmana bingehîn a pergala hîdrolîk e. Ger pompeya neftê têk biçe, ew ê bandorê li xebata normal a pergalê bike û bibe sedema ku makîneya bendkirinê nekare zextê zêde bike. Pêdivî ye ku pompeya hîdrolîk were kontrol kirin, tamîrkirin an veguheztin.

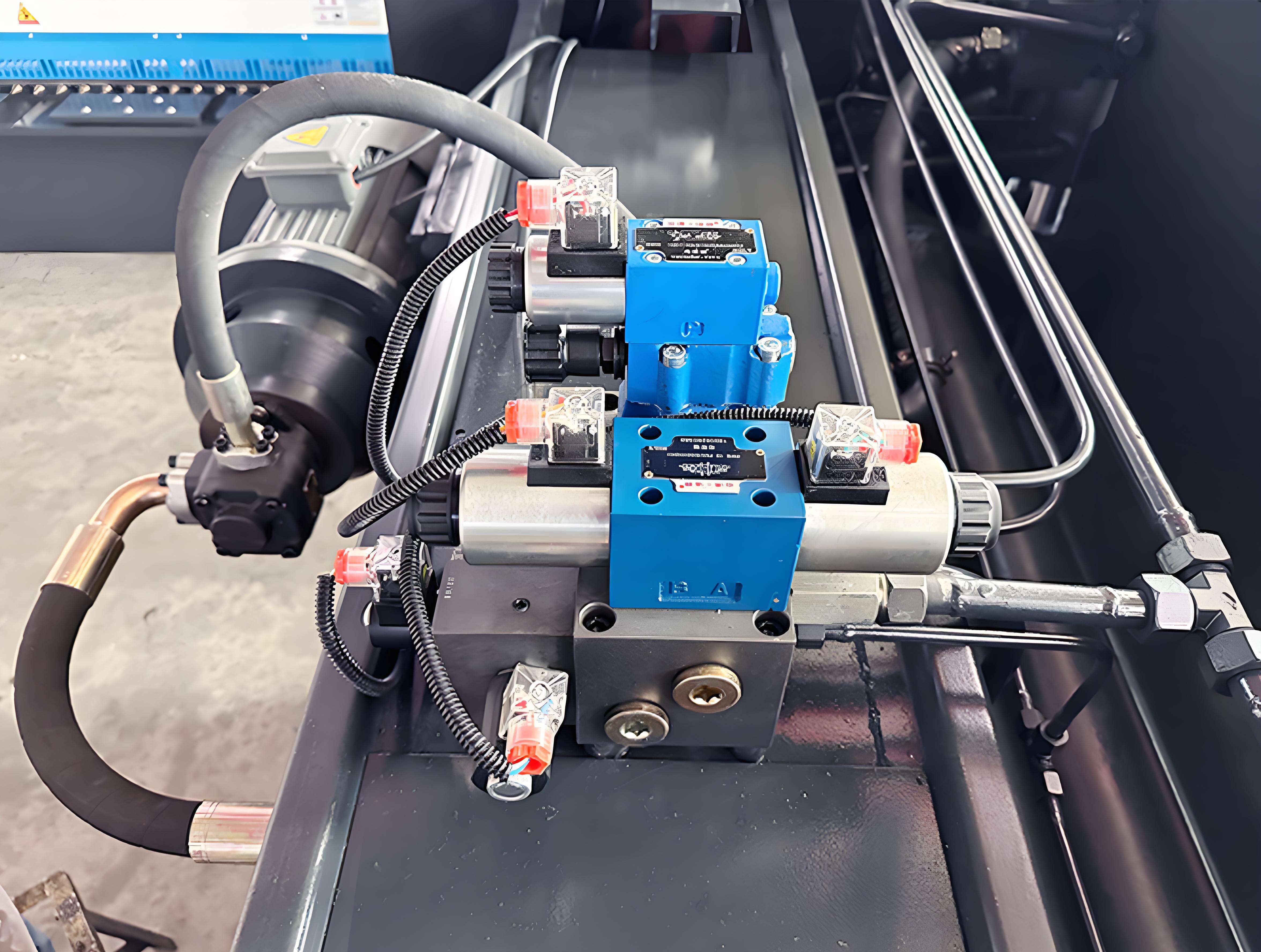

(3) Têkçûna koma valve.

Fonksiyona koma valve kontrolkirina herikîn, zext û tevgera makîneyê di pergala hîdrolîk de ye. Ger koma valve têk biçe, ew ê bandorê li xebata normal a pergalê bike û bibe sedema ku makîneya bendkirinê nikaribe zextê bike. Pêdivî ye ku valahiya hîdrolîk were kontrol kirin, tamîrkirin an veguheztin.

2. Têkçûna pergala veguhestinê

(1) Têkçûna pêkhateya mekanîkî.

Pergala veguheztinê ya makîneya bendkirinê ji gelek hêmanên mekanîkî pêk tê. Ger pêkhateyek mekanîkî têk biçe, ew ê bandorê li xebata normal a pergalê bike û bibe sedem ku makîneya bendkirinê nikaribe zextê bike. Pêdivî ye ku pêkhateya mekanîkî ya xelet were kontrol kirin, tamîrkirin an veguheztin.

(2) têkçûna sensor.

Sensorê makîneya bendkirinê amûra ketin û derketinê ya pergala kontrolê ye. Ger senzor têk biçe, dê pergala kontrolê bi rêkûpêk nexebite, di encamê de makîneya bendkirinê nikaribe zextê bike. Pêdivî ye ku senzorê xelet were kontrol kirin, tamîrkirin an veguheztin.

3. Pirsgirêka leakage seal Cylinder

Dema ku mora silindirê pîr bibe û xira bibe, dê silindir biherike, di encamê de makîneyê nikaribe zextê bike. Pêdivî ye ku mora silindirê were kontrol kirin an veguheztin.

4. Têkçûna pergala kontrola amûran.

Ger pergala kontrolê ya makîneya bendkirinê têk biçe, dê amûr bi rêkûpêk nexebite, di encamê de makîneya bendkirinê nikare zextê bike. Pêdivî ye ku pergala kontrolkirina amûran were kontrol kirin û tamîr kirin.

5. Operasyona neheq ji hêla operator.

Ger operator bi xeletî bixebite, makîneya bendkirinê dê nikaribe zextê bike. Pêdivî ye ku perwerdehî û rêveberiya operator were bihêz kirin da ku ji xeletî dûr nekevin.

6. Astengkirina Parzûnê.

Dema ku parzûna li ketina rûnê di tanka neftê de were asteng kirin, pompeya rûnê têk diçe û makîne dê nikaribe zextê bike. Pêdivî ye ku parzûn bi rêkûpêk were paqij kirin.

Bi kurtasî, têkçûna makîneya bendavêtinê ji ber zextê dibe ku ji hêla gelek sedeman ve were çêkirin, ku pêdivî ye ku ji gelek aliyan ve were lêkolîn kirin û çareser kirin, wekî pirsgirêkên pergala hîdrolîk û têkçûna pergala veguheztinê. Tenê bi dabînkirina xebata normal a alavan re em dikarin çêtir karên pêvajoyê temam bikin û karbidestiya hilberînê baştir bikin. Ger pirsên we hebin, hûn dikarin bi me re jî têkilî daynin da ku ji we re bibin alîkar ku hûn pirsgirêkên makîneyê çareser bikin.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY