Makîneya bendkirinê makîneyek hîdrolîkek giran e ku di pîşesaziya hilberîna metalê de ye. Ew amûrek pîşesazî ya giran e ku hewceyê lênihêrîna birêkûpêk e. Fêmkirina pêvajoya lênêrînê ya makîneya bendkirinê parçeyek girîng a xwedîkirin û karanîna makîneya benderê ye.

28 şîretan ji bo lênihêrîna makîneya bendkirinê parve bikin

1. Paqijkirina makîneyê bi rêkûpêk

Bi rêkûpêk rûbera makîneya guheztinê û rûbera qalibê bi qumaşek paqij an firçeyek nerm paqij bikin da ku pêşî li kombûna toz û bermayiyan bigirin, ku dê bibe alîkar ku temenê makîneyê dirêj bike.

2. Parçeyên tevgerê kontrol bikin û rûnê

Bi rêkûpêk pîvana paşîn, rêçên rêber û beşên din ên gerok ên makîneya bendkirinê kontrol bikin û li gorî hewcedariyê wan rûn bikin. Bikaranîna rûnê rast dikare cilê kêm bike û xebata bêkêmasî misoger bike.

3. Cihê xebatê paqij û paqij bihêlin

Piştrastkirina ku cîhê kar paqij û bê çopê bê hiştin dikare pêşî li qezayan bigire û karbidestiya kar baştir bike.

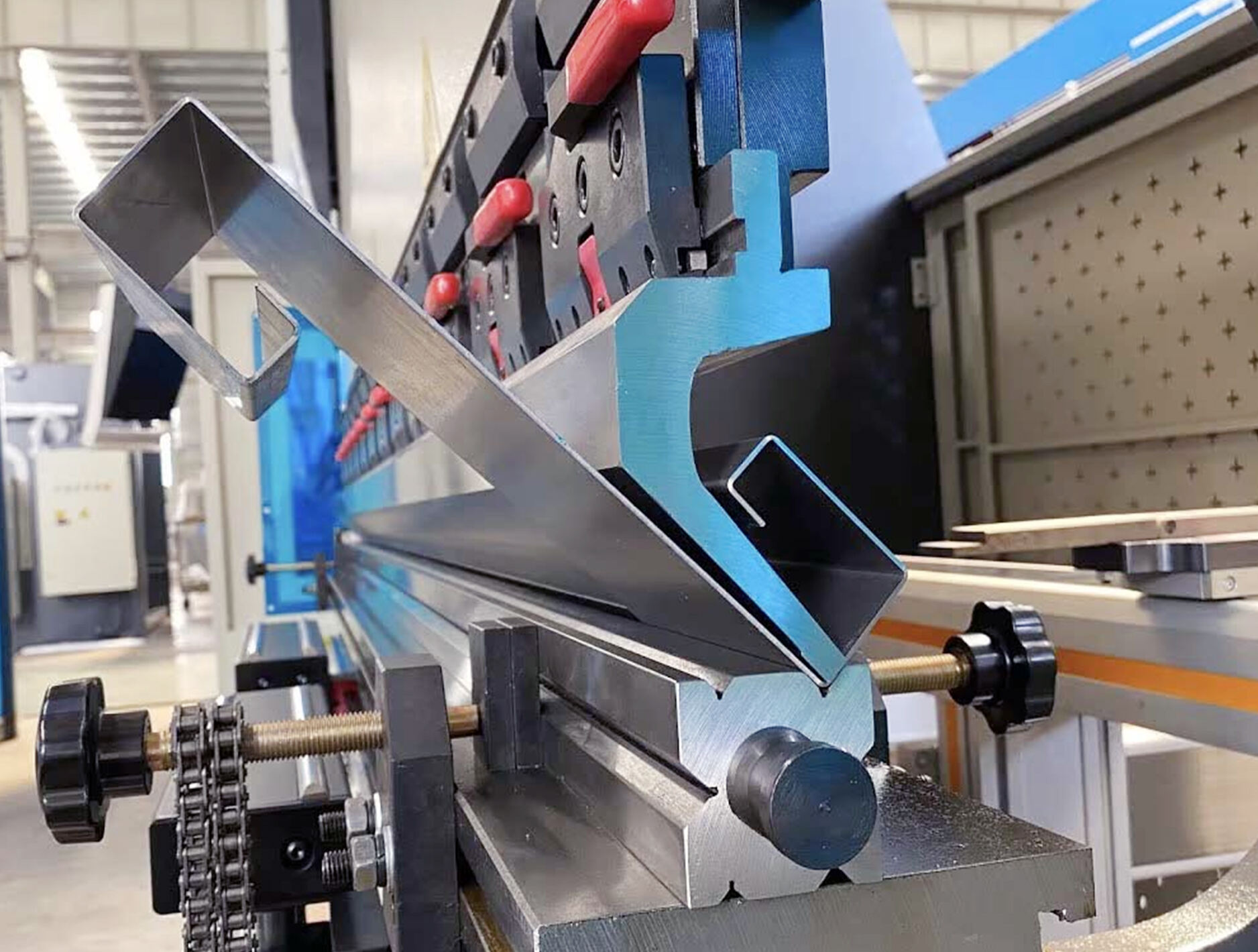

4. Li şûna qalibên westiyayî

Bi rêkûpêk cilbûna qaliban kontrol bikin û di wextê de qalibên xweyî biguherînin. Bikaranîna qalibên bi hêz-bilind dikare bandor û rastbûna çêtir peyda bike.

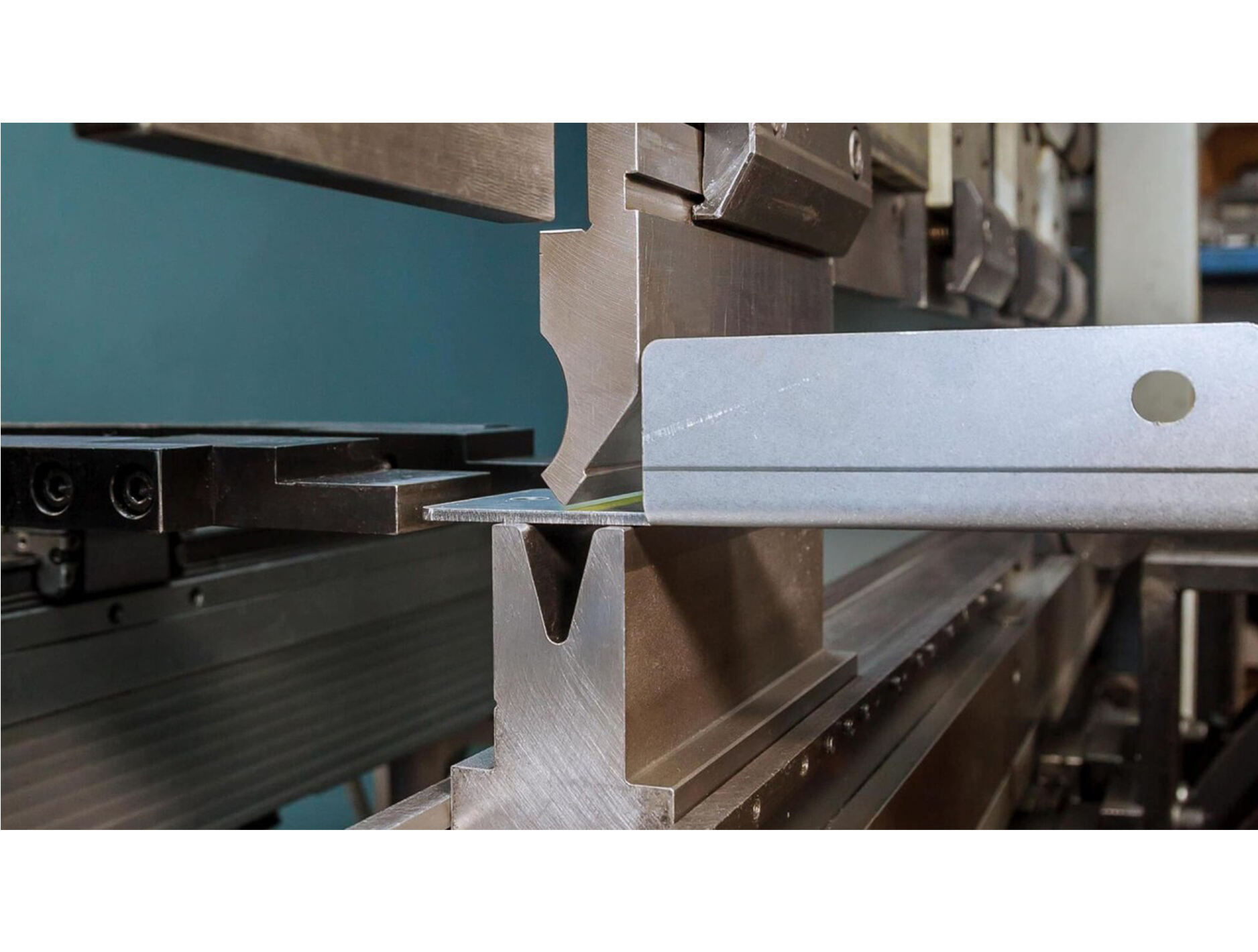

5. Kêlkirina goşeya bendkirinê

Bi rêkûpêk goşeya guheztinê binihêrin û kalibr bikin da ku pê ewle bin ku goşeya guheztinê ya perçeya xebatê rast e. Calibration dikare bi karanîna gonîometre an amûrên din ên pîvanê were kirin.

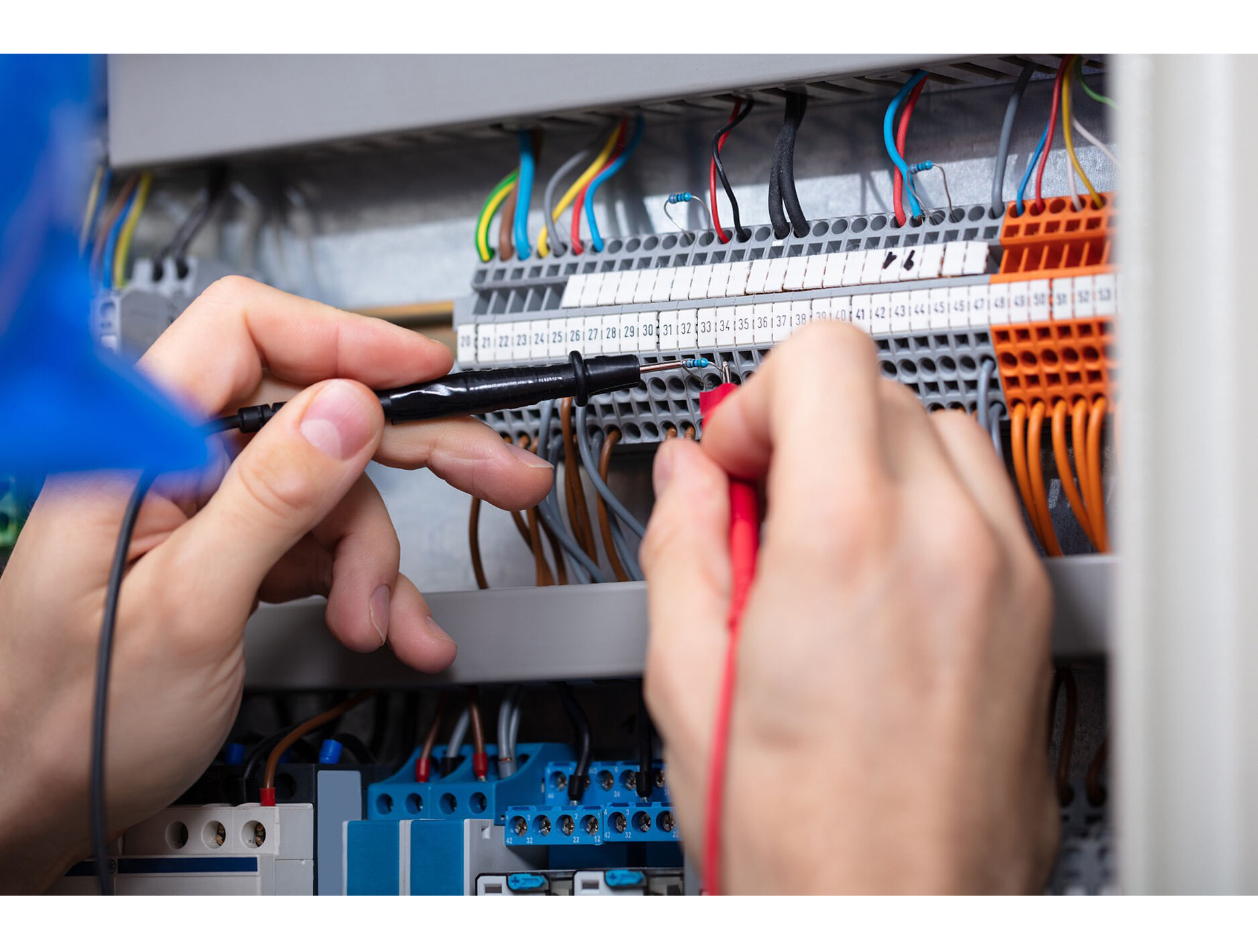

6. Têkiliya elektrîkê kontrol bikin

Girêdana elektrîkê ya makîneya bendkirinê bi rêkûpêk kontrol bikin da ku pê ewle bibin ku hemî têl zexm û pêbawer in. Heke pirsgirêk hatin dîtin, tavilê wan tamîr bikin.

7. Pergala hîdraulîk biparêzin

Bi rêkûpêk pergala hîdrolîk a makîneya guheztinê, di nav de asta rûnê hîdrolîk, lûle, morkirin, hwd kontrol bikin.

8. Parçeyên xwar biguherînin

Ji nêz ve çavdêriya pêkhateyên cihêreng ên makîneya çeqandinê, wek hêlîn, rêlên rênîşander, hwd. Dema ku nîşanên kinbûnê hatin dîtin, divê ew di wextê de werin guheztin da ku zirarek mezin nebînin.

9. Parçeya xebatê ji zirarê biparêzin

Piştrast bikin ku qalib bi pêbawerî sabît e da ku di dema pêvajoya çewisandinê de ji jicîhûwarkirin an zirara perçeya xebatê dûr nekevin.

10. Bi rêkûpêk asta makîneyê pîvandin

Asta bikar bînin da ku bi rêkûpêk asta makîneya bendkirinê kontrol bikin û ger hewce bike wê sererast bikin. Ev alîkar dike ku xebata stabîl a makîneyê bicîh bîne.

11. Amûrên parastina ewlehiyê kontrol bikin

Bi rêkûpêk amûrên parastina ewlehiyê yên cihêreng, wekî amûrên parastina fotoelektrîkî, deriyên ewlehiyê, hwd., kontrol bikin da ku ew di rewşek baş a xebatê de ne.

12. Pergala kontrolê biparêzin

Bi rêkûpêk pergala kontrolê ya makîneya bendkirinê kontrol bikin û biparêzin da ku pê ewle bibin ku pergala kontrolê rast û pêbawer e.

13. Parçeyên yedek hilînin

Ji bo guheztin û tamîrkirina demkî malzemeyên ku bi gelemperî têne bikar anîn û parçeyên lixwekirinê amade bikin.

14. Parastin û lênêrîna tomar

Qeydên lênêrînê û lênêrînê yên berfireh saz bikin, di nav de şert û mercên tamîrkirinê, parçeyên guheztinê, daneyên kalibrasyonê, hwd. Ev dibe alîkar ku hûn rewşa makîneyê fam bikin û pêşî li pirsgirêkan bigirin.

15. Maqûl planên hilberînê saz bikin

Bi maqûl planên hilberînê saz bikin, ji zêdebarkirina makîneya guheztinê dûr bixin, û ji bo lênihêrînê bi guncan sekinîn saz bikin.

16. Operatorên trênê

Piştrast bikin ku operatoran perwerdehiya pîşeyî wergirtine û rêgezên xebitandin û parastinê yên rast serdest e.

17. Qalibê rast bikar bînin

Hilbijartina qalibê rast û qalibê jêrîn li gorî materyalên cihêreng, stûrbûn û dirêjahiyan dikare bandora guheztinê baştir bike û jiyana karûbarê qalibê dirêj bike.

18. Kontrolkirina bi rêkûpêk paralelîzma bilindahiya belaş a makîneya kêşanê dê bibe alîkar ku rasterastiya slidera makîneya bendkirinê biparêze.

19. Bala xwe bidin qalîteya xebatê

Berî ku perçeya xebatê biqelînin, bi baldarî maddî, mezinahî, û rewşa rûbera perçeya xebatê kontrol bikin da ku ji ber pirsgirêkên kalîteya xebatê ji têkçûnê dûr nekevin.

20. Amadekariyên xwe bikin

Berî ku hûn dest bi xebata bendkirinê bikin, pê ewle bin ku we amadekariyên têr, wek pîvandin, nîşankirin, û rastkirin, kirine.

21. Bi rêbazên xebitandina ewlehiyê re tevbigerin

Bi tundî rêgezên xebitandina ewlehiyê yên makîneya bendkirinê bişopînin, alavên parastinê yên kesane rast bikar bînin, û pêşî li qezayên ewlehiyê bigirin.

22. Amûrên pîvanê bi rêkûpêk kalibr bikin

Bi rêkûpêk amûrên pîvandinê yên cûrbecûr kontrol bikin û kalibr bikin, wek calipers vernier, qaîdeyên goşeyê, hwd., da ku rastbûna daneyên pîvandinê piştrast bikin.

23. Pêvajoya bendkirinê çêtir bikin

Li gorî rewşa hilberînê ya rastîn, bi domdarî pêvajoya bendkirinê xweştir bikin da ku karbidestiya hilberînê û kalîteya hilberê çêtir bikin.

24. Rûyê xebatê biparêzin

Bi rêkûpêk rûbera xebatê ya makîneya çeqandinê paqij bikin û biparêzin da ku ji zirara ku ji ber şûştinê an qutbûna perçeya kar çêdibe dûr nekevin.

25. Bala xwe bidin şert û mercên jîngehê

Piştrast bikin ku germahiya hawîrdora xebatê, şilbûn, ronahiyê û şertên din ên makîneya bendkirinê baş in, ku ji xebata aram a makîneyê re dibe alîkar.

26. Planek acîl baş çêbikin

Plansaziyek awarte ya bêkêmasî pêşve bixin da ku zû bersivê bidin û bi têkçûnên makîneyê an rewşên ne normal re mijûl bibin.

27. Bi rêkûpêk çarçoveyê kontrol bikin

Bi rêkûpêk deformasyon û şilbûna çarçoweya makîneya bendkirinê kontrol bikin, di wextê de pirsgirêkan bibînin û wan tamîr bikin.

28. Adetên xebatê yên baş biparêzin

Adetên xebatê yên baş ên operatoran, wek paqijkirina birêkûpêk, tamîrên piçûk, hwd., ku ji dirêjkirina jiyana karûbarê makîneyê re dibe alîkar, çandin.

Bi kurtasî, bi navgîniya 28 serişteyên jorîn, hûn dikarin makîneya bendkirinê bi bandor biparêzin û bidomînin, jiyana karûbarê wê dirêj bikin, û karîgeriya hilberînê û kalîteya hilberê baştir bikin. Ger hûn di xebata rastîn de bi pirsgirêkek re rû bi rû bimînin, ji kerema xwe bi me re têkilî daynin û em ê hewl bidin ku ji we re bibin alîkar.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY