Bagaimana cara membengkokkan lembaran baja tahan karat?

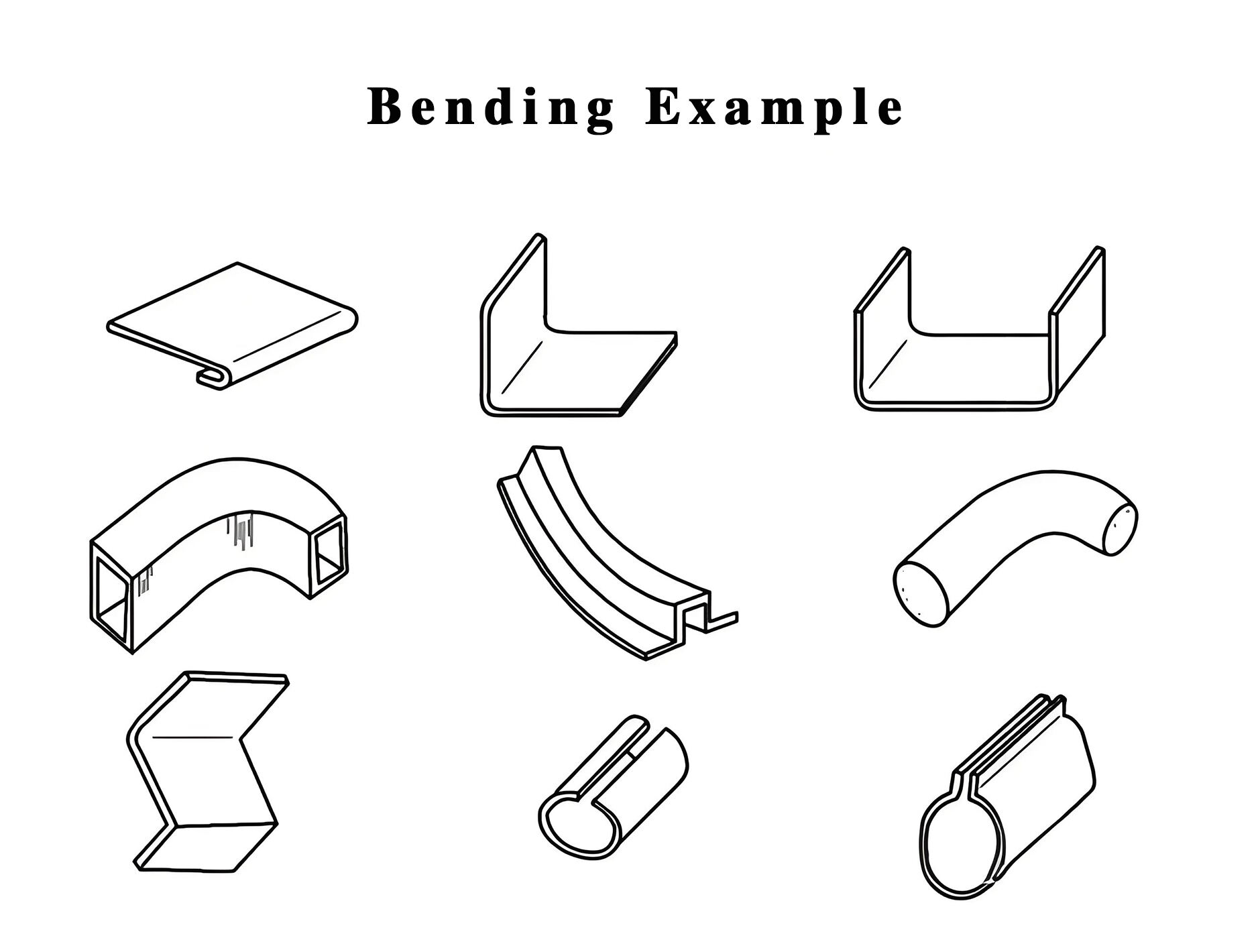

Seiring dengan perkembangan masyarakat, bentuk produk yang kita butuhkan juga mengalami perubahan dalam berbagai hal. Di antara semuanya, pembengkokan logam adalah yang paling umum, termasuk pembengkokan lembaran logam, pembengkokan pipa, pembulatan lembaran logam, ekstrusi profil, dll.

Proses apa saja yang terjadi pada pembengkokan lembaran logam?

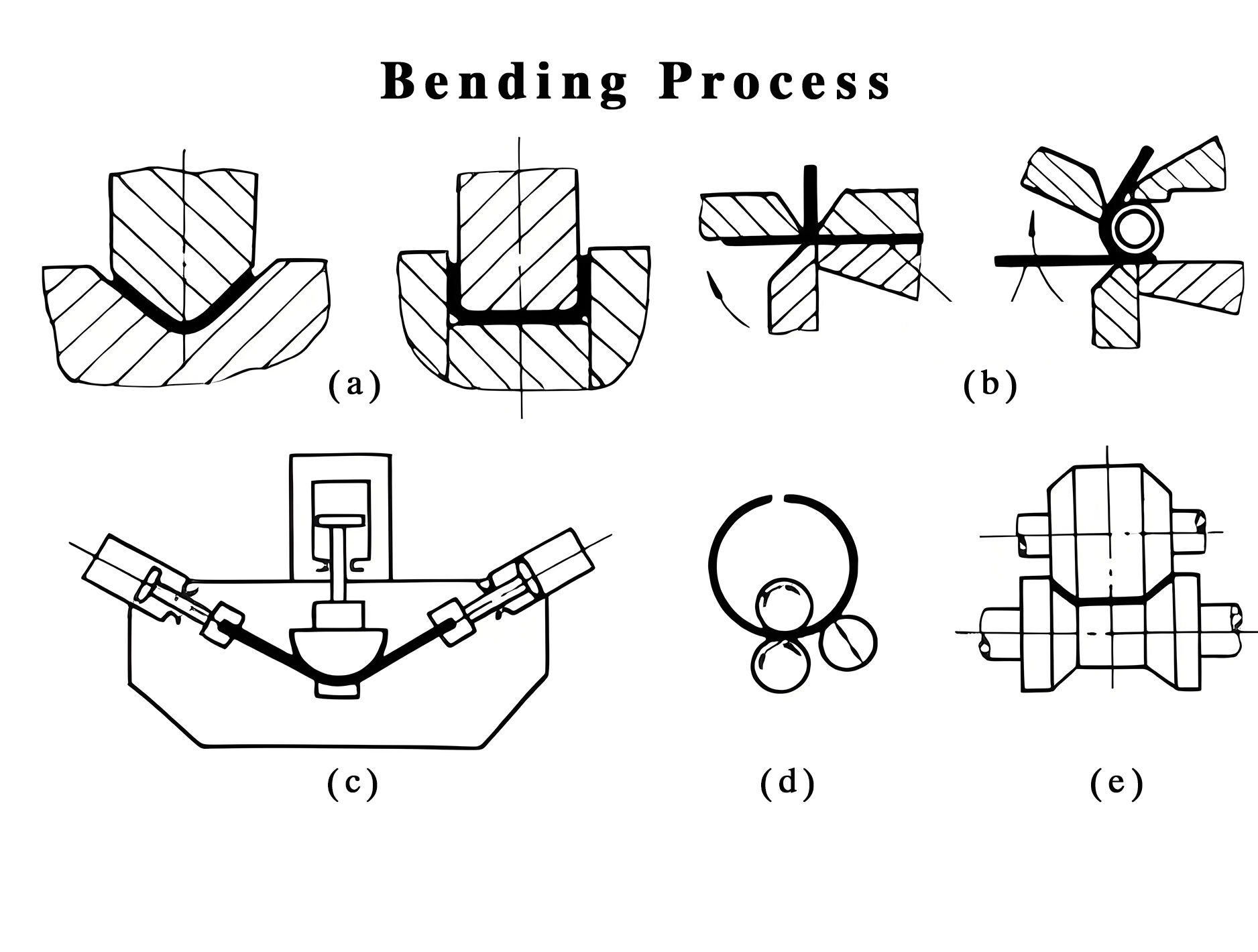

1. Pembengkokan biasa: Pembengkokan konvensional adalah dengan menggunakan Press Brake untuk membengkokkan lembaran logam menjadi 90°.

2. Pembengkokan perataan: Tekuk lembaran logam menjadi 30° terlebih dahulu, lalu ratakan sudut 30°. Jenis pembengkokan ini memerlukan pisau tajam di bagian atas dan cetakan perataan di bagian atas. Tujuan pembengkokan perataan adalah untuk meningkatkan kekuatan keseluruhan lembaran logam.

3. Pembengkokan engsel: Cetakan engsel khusus diperlukan untuk melakukan beberapa pembengkokan guna membentuk engsel.

4. Pembengkokan pembentukan satu kali: Untuk memaksimalkan efisiensi, cetakan pembentukan dapat dibuat berdasarkan bentuk produk, dan bentuk akhir produk lembaran logam dapat dicapai hanya dengan satu kali pembengkokan.

5. Pembengkokan busur: Ada dua metode pembengkokan untuk pembengkokan ini. (a) Hitung sudut pembengkokan dan ukuran sumbu X setiap langkah sesuai dengan ukuran busur produk, lakukan pembengkokan multi-langkah, dan terakhir tekuk busur. Ini adalah metode yang paling hemat biaya, tetapi efisiensinya tidak tinggi dan sulit; (b) Biarkan produsen menyesuaikan cetakan busur secara langsung sesuai dengan ukuran busur produk lembaran logam. Metode ini lebih efisien, dan kualitas serta tampilan produk juga ditingkatkan.

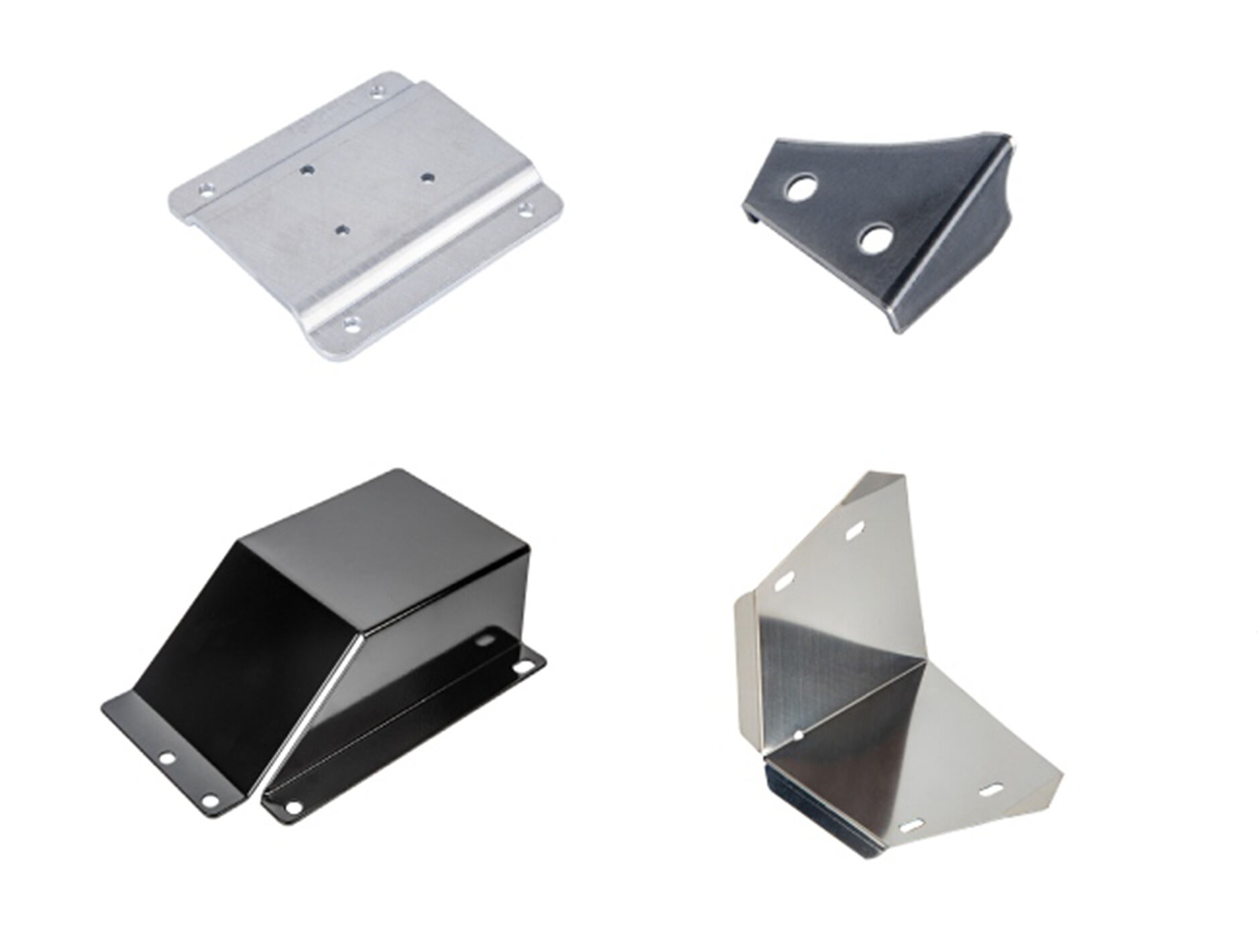

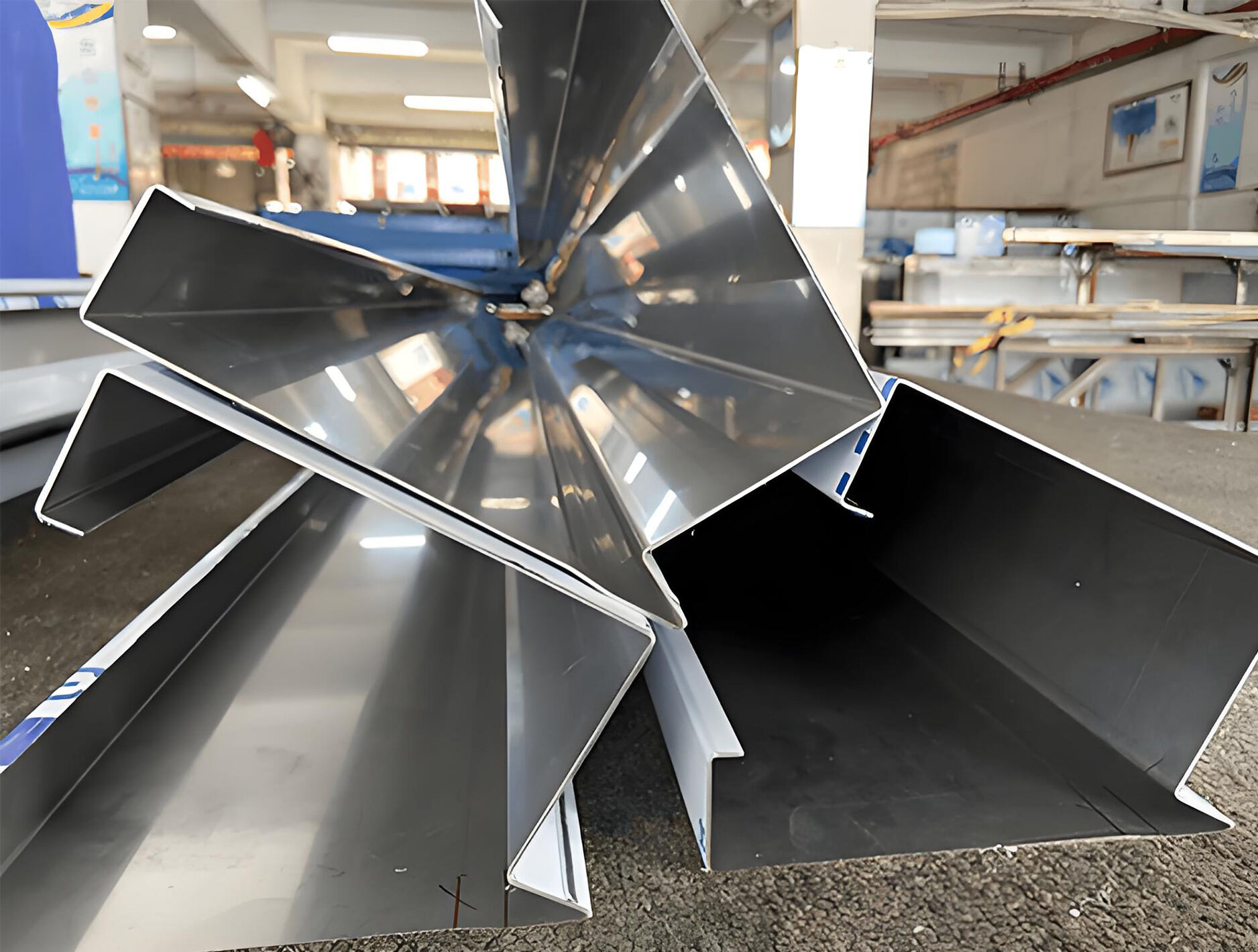

Pembengkokan baja tahan karat:

Sebagai material logam berkekuatan tinggi dan tahan korosi, baja tahan karat banyak digunakan di berbagai bidang industri. Akan tetapi, saat menggunakan Press Brake untuk membengkokkan baja tahan karat, beberapa masalah sering kali ditemui. Berikut ini adalah ringkasan dan solusi terkait yang diberikan. Semoga bermanfaat bagi Anda.

1. Goresan permukaan

Baja tahan karat rentan terhadap goresan dan abrasi permukaan selama proses pembengkokan. Alasan utamanya meliputi:

- Keausan atau desain perlengkapan yang tidak tepat

- Gesekan berlebihan antara benda kerja dan perlengkapan

- Debu atau benda asing pada permukaan benda kerja

- Slot cetakan terlalu kecil

Solusi:

- Periksa dan ganti perlengkapan secara teratur

- Mengoptimalkan desain perlengkapan untuk mengurangi area kontak antara benda kerja dan perlengkapan

- Jaga permukaan benda kerja dan cetakan tetap bersih, dan bersihkan benda asing yang ada di permukaan secara teratur

- Untuk produk dengan persyaratan tinggi, disarankan untuk menggunakan cetakan tekuk tanpa jejak atau film tanpa jejak

2. Deformasi material, sudut tekuk tidak memenuhi standar

Baja tahan karat rentan terhadap deformasi selama proses pembengkokan. Alasan utamanya meliputi:

- Perhitungan jumlah pra-tekukan yang tidak tepat

- Kekuatan pantul yang berlebihan dari baja tahan karat itu sendiri

- Pemilihan takik cetakan yang tidak tepat

Larutan:

- Hitung jumlah pra-tekukan secara akurat sesuai dengan karakteristik material

- Press Brake perlu dilengkapi dengan kompensasi mekanis, yang akan sangat meningkatkan kelurusan dan estetika produk

- Slot baja tahan karat terlebih dahulu dan kemudian tekuk, yang akan sangat meningkatkan kelurusan dan estetika produk, dan juga mengurangi hilangnya Press Brake

Singkatnya, saat menggunakan Press Brake untuk memproses baja tahan karat, perlu mempertimbangkan banyak faktor seperti karakteristik material, parameter proses, dan kondisi peralatan, serta mengambil solusi yang tepat guna memastikan kualitas pemrosesan dan efisiensi produksi.

Fitur Produk

Hot Berita

-

Arab Saudi-WC67K 100T 3200 NC Press Brake & QC12K-4x3200 Shearing Machine & 3x3100 Folding Machine

2024-11-11

-

USA-PANEL 1400PA3-DA PUSAT PEMBENGKAKAN

2024-10-28

-

Argentina-WC67K 125T 3200 CNC Press Brake & Mesin Geser QC12K-4X3200

2024-10-25

-

Penggunaan utama dan pengembangan pusat pembengkokan

2024-10-24

-

Mesin Press Rem CNC Indonesia-WC67K-30T 1600/63T 2500/100T3200/160T 3200

2024-10-21

-

Cara mengatasi kurangnya tekanan pada Press Brake

2024-10-15

-

Cara merawat Press Brake: 28 tips agar Press Brake tetap dalam kondisi prima

2024-10-04

-

Meksiko WC67K 80T 3200 NC Press Brake & Mesin Geser QC12k-6×3200

2024-09-26

-

Panduan Lengkap tentang Pembengkokan dan Pembentukan

2024-09-26

-

Selamat datang pelanggan India untuk mengunjungi pabrik kami

2024-09-23

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY