Abkant Pres yapı analizi

Abkant Pres hepimizin bildiği gibi sac işlemede kullanılan bir makinedir. Manuel bükme makineleri, hidrolik bükme makineleri ve CNC bükme makineleri dahil olmak üzere birçok bükme makinesi türü vardır. Modern endüstrinin gelişmesiyle birlikte CNC Abkant Pres sektörde baskın bir konuma sahiptir. Avantajları, üretim verimliliğini büyük ölçüde artıran hızlı hız, yüksek hassasiyet ve düşük arıza oranıdır. Bu yazımızda CNC elektro-hidrolik Abkant Abkantın yapısal analizini yapacağız.

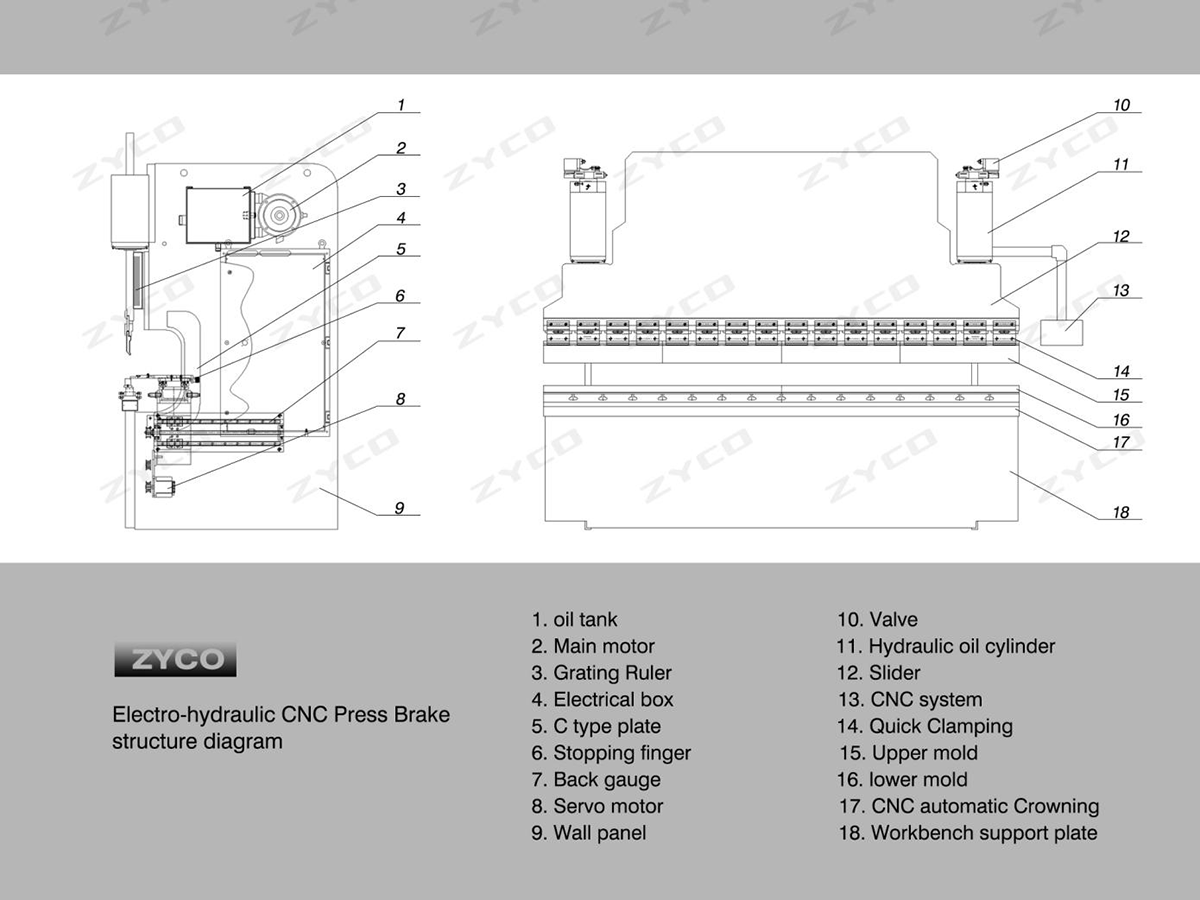

1、Makine çerçevesi

Makinenin çerçevesi, her iki taraftan duvar panellerine bağlanan ve tezgah destek plakasına kaynak yapılarak çerçeve oluşturacak şekilde bir yakıt deposundan oluşmaktadır. Çerçevenin kaynaklanması doğrudan makinenin temel gücünü belirler. Çerçeve kaynaklandıktan sonra bitirmeden önce deformasyonu ortadan kaldırmak için işlenmesi gerekir. Makinenin dikeyliğini ve paralelliğini sağlayın.

2、Çalışma Tezgahı

Tezgah şu şekilde ayrılmıştır: otomatik mekanik Taçlandırma tezgahı, manuel mekanik Taçlandırma tezgahı ve sıradan çalışma tezgahı. Temel işlevleri aynı olup, alt kalıba destek ve iş olarak kullanılırlar. Sıradan tezgahın herhangi bir işlevi yoktur. Mekanik Bombeleme tezgahının avantajı, bükülmüş iş parçasının ara açısını telafi ederek bükme iş parçasını daha hassas hale getirebilmesidir.

3, Kaydırıcı

Kaydırma bloğu makine hareketinin ana yapılarından biridir. Tüm bükme hareketini strok ile birleştirmek için hızlı kelepçeyi ve üst kalıbı takmak için kullanılır. Hareketi yağ silindiri tarafından tahrik edilir ve her iki tarafı da yağ silindirine bağlıdır. Kaydırma bloğunun ana doğruluğu, düzlüğün kontrolüdür. Kontrol, üst kalıbın düzlüğünü ve bükülmüş iş parçasının düzlüğünü doğrudan etkileyecektir.

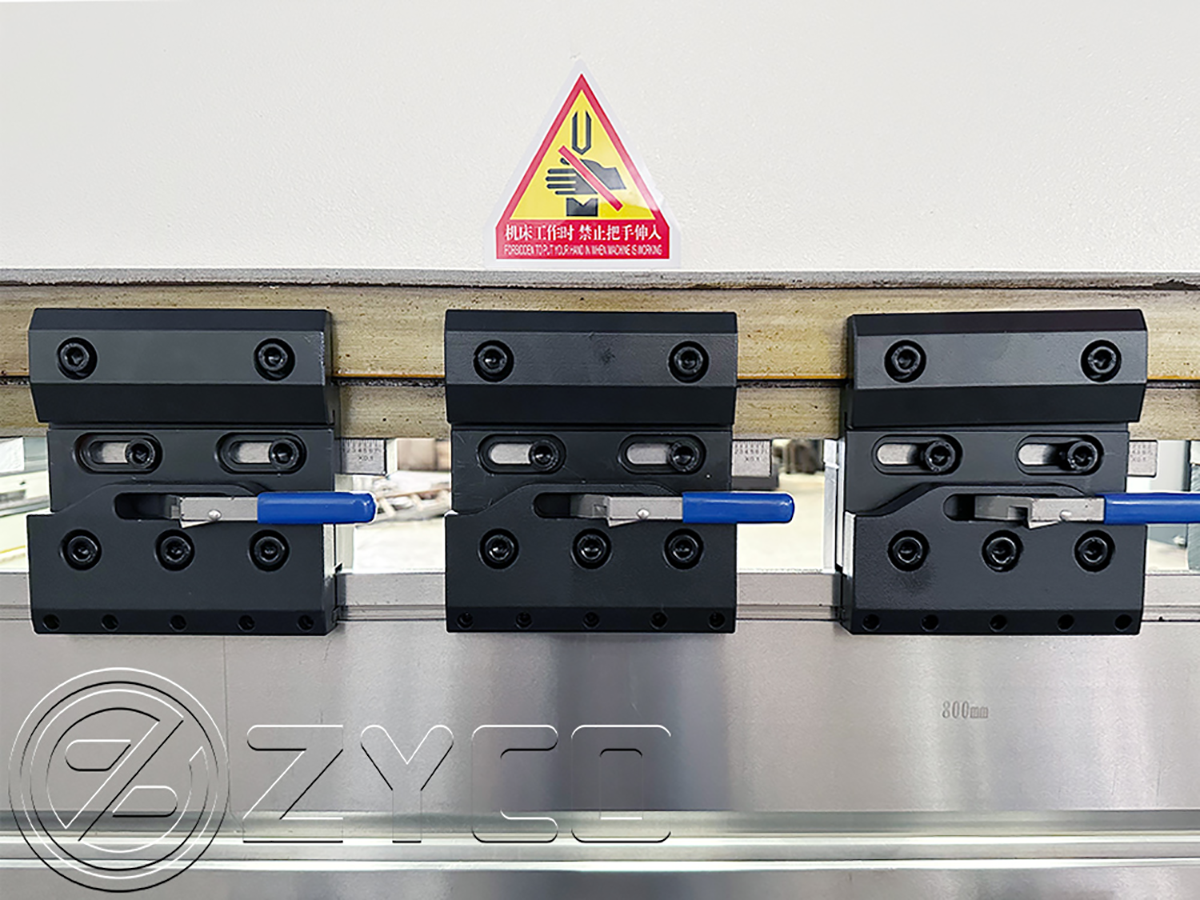

4、 Takım Kelepçeleri

Kelepçeler sıradan kelepçelere ve hızlı kelepçelere ayrılır. Hızlı kelepçeler, yüksek verimlilik ve yüksek hassasiyetle en yaygın kullanılanlardır. Kelepçeler kaydırıcıya monte edilmiştir. Amaçları kalıbın her bölümünün kurulumunu ve entegrasyonunu tek bir yerde entegre etmektir. Kelepçelerin doğruluğu aynı zamanda kalıbın montaj doğruluğunu da doğrudan etkiler.

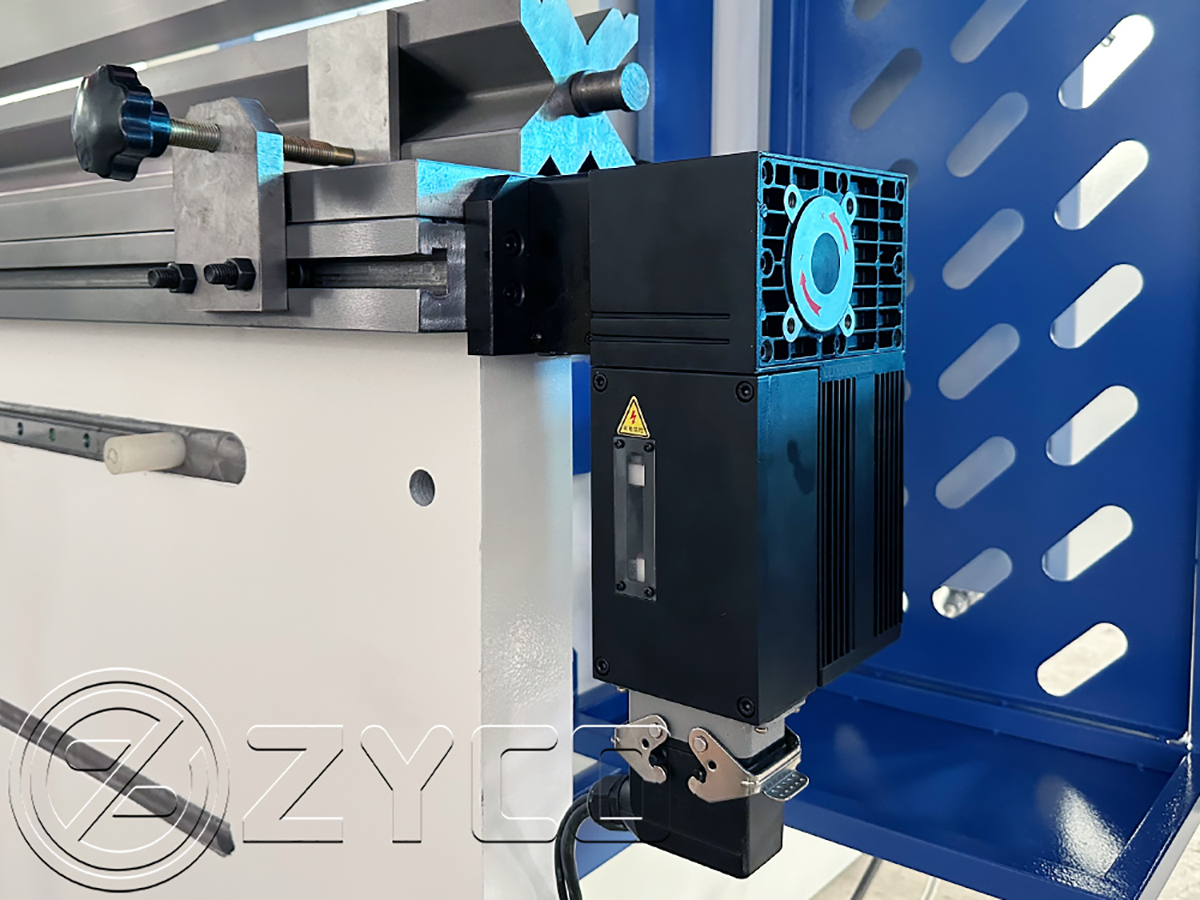

5、Arka Dayama

Bükme makinesinin arka dayama makinesinin önemli parçalarından biridir ve iş parçasını bükmek için gereken konumu ve uzunluğu kontrol etmek ve ayarlamak için kullanılır. Arka dayama makinenin arkasına monte edilir ve 1 eksen, 2 eksen, 4 eksen ve 6 eksen hareket modlarına sahiptir. Sürüş yöntemi, gerekli uzunluğu bilgisayar aracılığıyla girmek ve ardından hareket mesafesini kontrol etmek için servo motoru kullanmaktır. Bu nedenle CNC bükme makinesinin arka dayama bloklama doğruluğu çok yüksektir.

6、Kalıp

6、Kalıp

Bükme makinesinin çalışması için kalıp gereklidir. Üst kalıp ve alt kalıp olarak ikiye ayrılır. Üst kalıp fikstür üzerine monte edilir ve iş parçasını bükmek için kaydırıcının hareketini takip eder. Alt kalıp tezgah üzerine monte edilir. Alt kalıp yuvasının boyutunun, Plaka kalınlığına göre ayırt edilene göre seçilmesi gerekir.

7、Hidrolik Sistem

Hidrolik sistem, hidrolik silindirin basıncını ve akışını ve bükme makinesinin kızak hareketini kontrol eder. Ana motor, yağ pompası ve valf grubu önemli bileşenlerdir. Elektrik enerjisi ve mekanik enerji, silindirin basıncın amacına uygun hareketini sağlamak için motor ve yağ pompası aracılığıyla hidrolik basınca dönüştürülür.

8, Kontrol Sistemi

Kontrol sistemi, tüm hareket talimatlarını bükme makinesine gönderen beyindir. Komutları alabilir ve metin, sembol, sayı ve grafik biçiminde çıktı alabilir. Ayrıca makine inceleme ve onarımı kolaylaştıramadığında talimat kodlarının çıktısını da alabilir. Sistem, bükme amaçlarına ulaşmak için programlanabildiği gibi çeşitli programları da saklayabilir. Şu anda dijital, 2 boyutlu grafikler ve 3 boyutlu grafikler gibi programlama fonksiyonlarına yönelik seçenekler bulunmaktadır. Piyasada en yaygın kullanılanlar DA53T, DA66T, DA69T, CT8, CT12 ve CT15 kontrol sistemleridir.

9, Yağ silindiri

Yağ silindiri, hidrolik sistemin bileşenlerinden biri ve kaydırıcıyı hareket ettiren bileşenlerden biridir. Bükme sırasındaki basınç da yağ silindiri tarafından sağlanır. Yapısı silindir bloğu, silindir kapağı, piston kolu ve contalardan oluşur.

10、Izgara cetveli

Kaydırıcının çalışma konumunu geri beslemek ve kaydırıcı konumunu bilgisayara geri beslemek için kaydırıcının her iki tarafına ızgaralı cetvel takılıdır. Aynı zamanda bilgisayar, kaydırıcının belirtilen konuma doğru şekilde çalışmasını sağlamak için hedef değeri de hesaplayacak ve çıktısını alacaktır. Bükme doğruluğu tamamen ızgara ölçeğinden gelen geri bildirime bağlıdır.

Özet: Bu makale CNC bükme makinesinin yapısını ve analizini ayrıntılı olarak göstermektedir. Eğer acemiyseniz bu makaleyi dikkatlice okuyabilirsiniz, bu da bükme makinesini anlamanıza çok yardımcı olacaktır. ZYCO CNC Machinery Co. , Ltd. Bükme makinası sektöründe 30 yıllık teknik tecrübemiz ile makinalarımıza göz atabilir veya detaylı bilgi için satış personelimize danışabilirsiniz.

Önerilen Ürünler

Sıcak Haberler

-

Suudi Arabistan-WC67K 100T 3200 NC Pres Freni ve QC12K-4x3200 Kesme Makinesi ve 3x3100 Katlama Makinesi

2024-11-11

-

USA-PANEL 1400PA3-DA BÜKME MERKEZİ

2024-10-28

-

Arjantin-WC67K 125T 3200 CNC Pres Freni ve QC12K-4X3200 Kesme Makinesi

2024-10-25

-

Bükme merkezlerinin temel kullanımları ve gelişimi

2024-10-24

-

Endonezya-WC67K-30T 1600/63T 2500/100T3200/160T 3200 CNC Pres Freni

2024-10-21

-

Pres Freninde basınç eksikliğiyle nasıl başa çıkılır

2024-10-15

-

Pres Freni nasıl korunur: Pres Frenini mükemmel durumda tutmak için 28 ipucu

2024-10-04

-

Meksika WC67K 80T 3200 NC Pres Freni ve QC12k-6×3200 Kesme Makinesi

2024-09-26

-

Bükme Şekillendirmeye Kapsamlı Kılavuz

2024-09-26

-

Fabrikamızı ziyaret etmek için Hintli müşterilere hoş geldiniz

2024-09-23

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY