Teu salawasna gampang uninga mana mesin logam narilep bakal ngalakukeun pakasaban pikeun anjeun, mun anjeun damel sareng bengkung-logam, tapi nyieun pilihan Anjeun cara kieu bener ngajadikeun bédana. Ieu dimana ZYCO asalna di. ngajadikeun mesin husus disebut puseur bending panel. Éta téh dipaké pikeun ngidinan Anjeun pikeun ngawangun pelat logam tina sagala rupa wangun. Ieu sababaraha tip penting pikeun ngabantosan anjeun milih pusat bending panel anjeun anu paling cocog sareng kabutuhan anjeun.

Kumaha Meuli Mesin Katuhu

Unsur kahiji anu kedah dipertimbangkeun nalika milih pusat bending panel nyaéta tujuan anu anjeun bakal dianggo. tipena béda mesin dianggo hadé pikeun proyék-proyék béda. Contona, upami Anjeun keur kaayaan lambaran ipis logam, Anjeun bisa kabur tanpa mesin well-diwangun jeung beurat. Tangtosna upami anjeun hoyong ngabengkokkeun pelat logam anu langkung gendut, anjeun bakal hoyong pencét langkung industri anu tiasa ngalakukeun jinis padamelan ieu.

Pikirkeun ogé ukuran naon sareng kumaha éta bakal ngabentuk potongan-potongan anu ngagulung. ZYCO gaduh mesin anu tiasa ngolah seueur bentuk sareng ukuran anu béda, janten anjeun pasti bakal mendakan anu cocog sareng kabutuhan anjeun. Anjeun bakal ngadamel pilihan anu langkung saé anu bakal anjeun dukung sareng proyék anjeun ku cara mikir kumaha anjeun tiasa nganggo mesin.

Fitur penting tina mesin modern

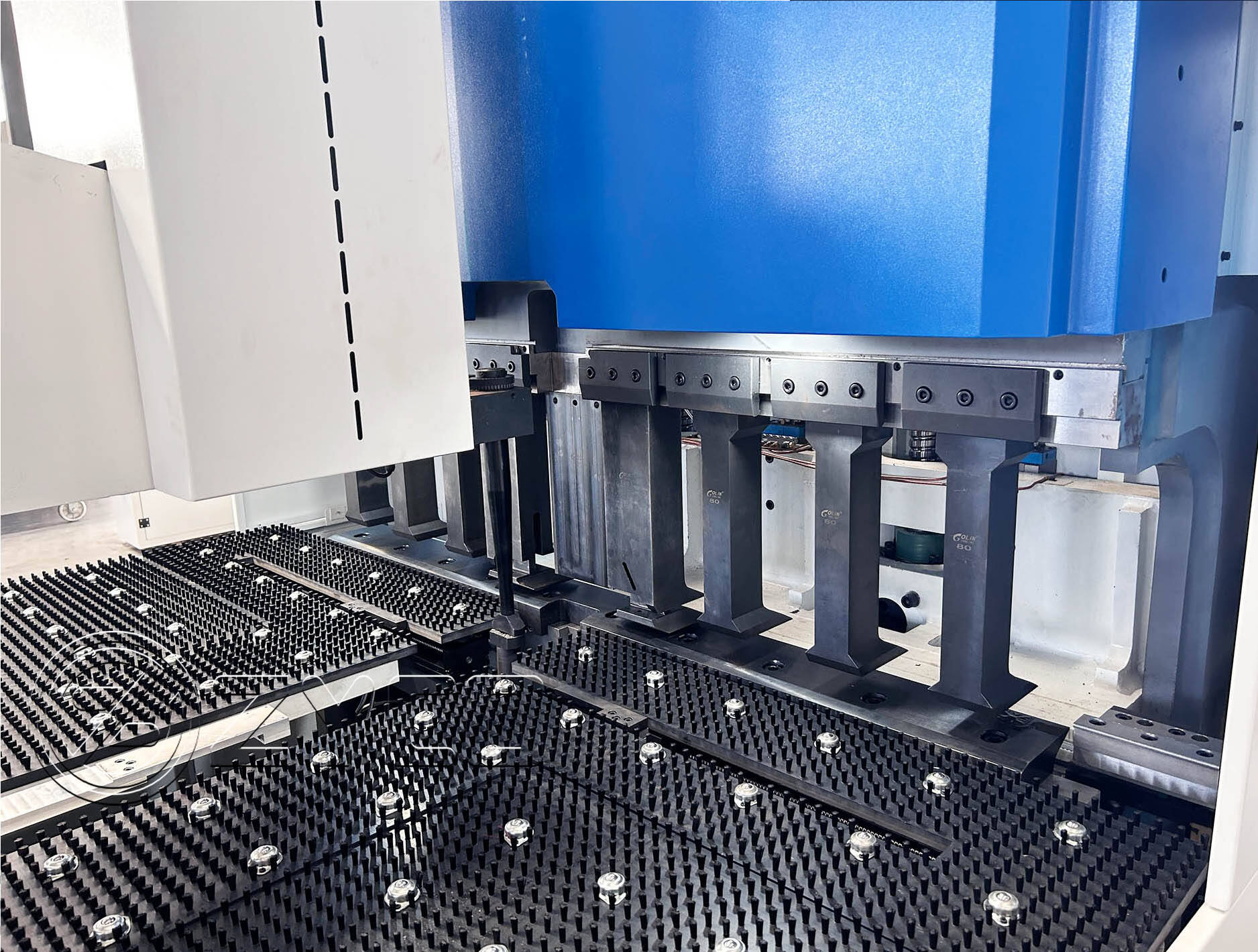

Ogé, puseur bending panel modern dilengkepan loba fungsi nu betah tur hadé operasi na dibandingkeun generasi heubeul. Ganti alat otomatis, sareng ieu mangrupikeun salah sahiji fitur anu penting pisan. Éta hartosna, mesin ieu tiasa ngagentos antara alat anu béda-béda nyalira tanpa anjeun kedah ngarobih unggal waktos. Bakal nyalametkeun anjeun eunteung pikeun ngirim duit. ZYCO méré Anjeun sauntuyan mesin kalawan nepi ka sapuluh stasiun alat, jadi pilihan téh sagemblengna Hormat mun anjeun merlukeun parabot béda.

Hal konci séjén pikeun milarian nyaéta deteksi ketebalan lambar otomatis. Fitur ieu ngabantosan katepatan tina bends anjeun, anu penting dina ngerjakeun logam. Ogé, sababaraha mesin kontemporer dilengkepan software programming calakan. Kalayan parangkat lunak ieu, anjeun tiasa ngarencanakeun tikungan anjeun langkung gampang sareng ngahémat waktos damel.

Tip pikeun Ngagunakeun Mesin Anjeun

Di handap ieu aya sababaraha hal anu anjeun tiasa laksanakeun pikeun ngajaga pusat bending panel anjeun lancar sareng éfisién, sawaktos éta dipasang. Aya sababaraha alat sareng asesoris penting anu anjeun peryogikeun, sapertos panyekel punch sareng palang bending, janten pastikeun anjeun gaduh anu sayogi. Upami anjeun gaduh sadayana anu anjeun peryogikeun, anjeun bakal ngahindarkeun sababaraha telat sareng tetep karya anjeun lancar.

Ngajaga workspace Anjeun rapih tur bersih oge mangrupakeun ide nu sae. Anjeun tiasa sacara gampil mendakan naon waé anu anjeun peryogikeun nalika gaw beresih, anu tiasa ngahémat waktos sareng ngamungkinkeun anjeun langkung éfisién di tempat kerja. Sareng anu terakhir, pertimbangkeun kéngingkeun sababaraha parangkat lunak anu bakal ngabantosan anjeun ngarencanakeun tikungan anjeun langkung saé. Tah, aya paribasa “Kerja Pinter Daripada Kerja Keras”.

Milih Mesin anu Kuat sareng Diandelkeun

Lamun anjeun milih pikeun investasi kana puseur bending panel, éta pohara penting pikeun milih mesin nu bakal ngawula ka pikeun sababaraha taun. A alus, mesin sturdy hartina anjeun teu bade kudu meuli nu anyar sakumaha mindeng, hartina hasil hadé tur kirang downtime. ZYCO specializes dina ngahasilkeun mesin awét sarta kualitas luhur. Éta ogé ngagunakeun bahan kualitas luhur sareng komponenana supados mesinna tiasa nyandak seueur hukuman salami mangtaun-taun.

Racine na Warby: Milih mesin katuhu pikeun jobs béda

Lamun nungkulan komponén logam tina ukuran béda jeung géométri, nyieun hiji pick hiji puseur bending panel nu boga kamampuhan pikeun ngaéksekusi sababaraha jobs. ZYCO boga mesin jeung sagala rupa ukuran ranjang jeung stasiun alat - hartina anjeun bisa ngabengkokkeun nanaon ti bagian hipu leutik nepi ka pelat beurat badag.

Nalika milih mesin, ogé ngitung ukuran sareng beurat bagian anu anjeun badé ngagulung. Anjeun ogé kedah mertimbangkeun kabutuhan khusus anu anjeun gaduh pikeun proyék-proyék anjeun. Anjeun bakal mungkas nepi ka mesin nu caters ka sadaya kabutuhan Anjeun ngan ku mikir ngaliwatan rinci ieu.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY