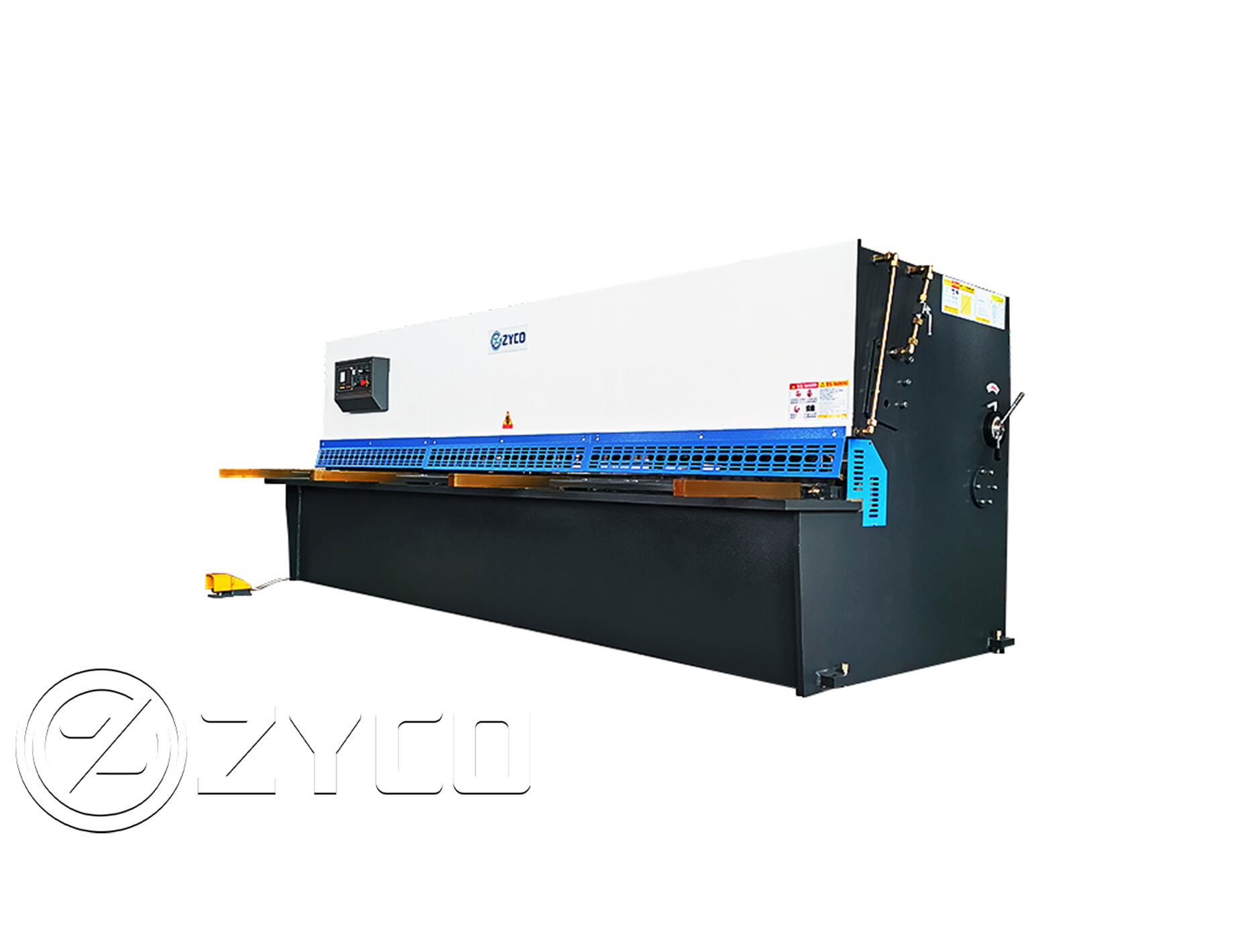

Знате како као да видите велику машину која сече метал на праве линије? Назив машине је хидраулична машина за шишање. Јединствена је машина алатка у обради метала, која ради помоћу хидраулике за бриљантно сечење лимова на плоче. Како ова машина ради и који је њен значај?

Шта је хидраулична машина за шишање?

Машина за хидрауличне маказе је састављена од многих битних делова који сарађују за смицање метала. Састоји се од једног главног дела који се зове систем. Он генерише енергију користећи течности. Хидраулични цилиндар користи течност која се упумпава у посуду за стварање притиска, који гура клип што доводи до кретања. Ово кретање је оно што омогућава машини да сече метал. За цилиндар је причвршћено оштро сечиво које се даље котрља по овим металним лимовима, секући их на свој начин.

Сама оштрица је још један важан аспект машине. Различити материјали који се користе за сечиво (према металу који се сече) Да би фабрика лима функционисала како треба, сечиво мора бити доброг квалитета. Будући да има оштру ивицу, ово омогућава маказама да направи чисте и глатке резове, а истовремено чува дуговечност свих урађених металних радова.

Увод у хидрауличну машину за шишање

Када први пут користите хидрауличну машину за шишање, морате знати три најважније ствари. Безбедност: безбедност је веома важна када радите са овом врстом машина. Када користите хидрауличну машину за шишање метала, не заборавите да носите сигурносне алате као што су рукавице, наочаре и чепићи за уши. Ова опрема обезбеђује заштиту од било каквих незгода или повреда. Поред тога, прави тренинг је кључан. Они ће вас обучити како да безбедно и правилно користите машину.

Затим ћете морати да процените коју величину машине требате. Одабир најпогодније величине за ваше потребе. Веће машине се могу користити за сечење масивнијих комада метала, али генерално имају већу цену и захтевају знатно више простора у вашој радњи. Мање машине су, с друге стране, јефтиније, али могу да раде са мекшим металом и имају мањи капацитет резања.

Када користити хидрауличну машину за шишање

Машине за хидрауличне маказе имају широку примену у обради метала што је последица вишеструких фактора. Користе се првенствено зато што обећавају изузетан степен прецизности и брзине, практично игноришући метал при сечењу. Веома су брзи и прецизни у резању метала, што има огроман значај за производне процесе. Ако треба да произведете много делова и сви морају да буду у равнини, онда су чисти резови неопходни.

Предности хидрауличних машина за шишање у производњи

Листа предности које хидрауличне машине за шишање нуди производној индустрији је огромна. Једна од највећих предности је та што су ове врсте веште у прављењу стотина/хиљада котлета у кратком временском периоду. Масовна производња, где много делова треба да се обложи одједном. Што мање времена потрошите на сечење метала, пре ће ваши пројекти бити готови.

Још једна предност је што хидраулична машина за шишање лимова има свестрану природу. Ове тестере могу да секу кроз много различитих стилова метала као што су челик, алуминијум и месинг. Користе се у великом броју апликација, као што је израда ауто делова и кухињских апарата – металних производа.

У међувремену, ако се о томе брине хидраулична машина за шишање, лако је. Једноставни задаци као што су повремена замена уља и уверавање да је ваше сечиво у исправном стању омогућиће звери да настави да коси тврду траву годинама. Дакле, компаније које треба да производе велику количину металних делова брзо и са изузетном исплативошћу треба да размотре улагање у ову најновију технологију — као што је горе поменуто, оне би за њих биле предност.

Све у свему, машине за хидрауличне маказе су незаменљива опрема у фабрици за производњу. Поуздани су, раде са скоро свим врстама лима и вероватно је најважнија ствар — јер су тако једноставни да их можете имати као одличан помоћни алат за своју радионицу. Ако изаберете хидрауличну машину за шишање, величина, капацитет сечења и безбедносне карактеристике су важне тачке које треба узети у обзир. Машина за хидрауличне маказе, са одговарајућом обуком и редовним одржавањем, помоћи ће вам да производите металне материјале врхунског квалитета за дужи период производног процеса испуњавајући све ваше техничке захтеве за метал.

ЗИЦО нуди мноштво хидрауличних машина за шишање које су скројене да испуне ваше захтеве за обраду метала. Непотребно је рећи да су наше машине дизајниране за најбоље могуће перформансе и једноставност, тако да можете брзо да креирате металне делове, а истовремено нуде низ опција. Сазнајте више о нашим производима и услугама, контактирајте нас данас.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY