Keskustelu Press Braken CNC-seurantatukiteknologiasta

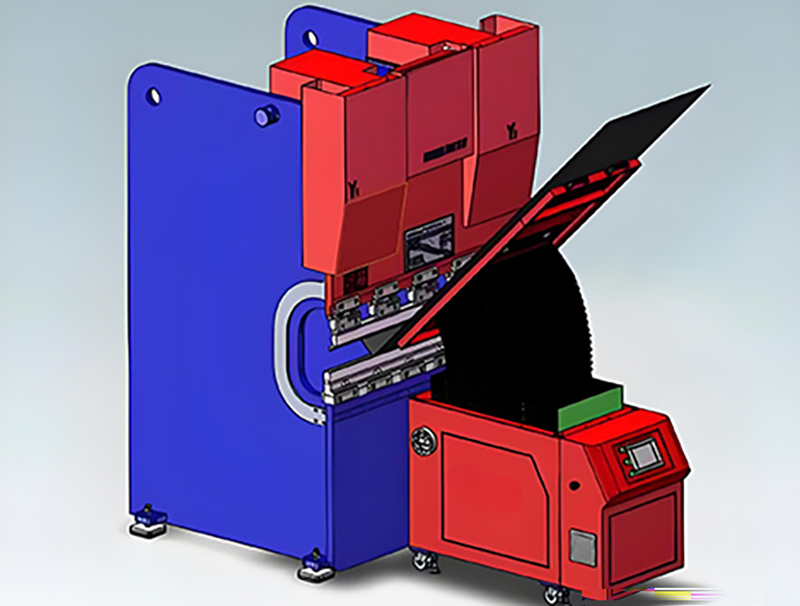

Taivutus on yleinen muovausprosessi metallinkäsittelyssä, jolla metallilevyjä tai -profiileja taivutetaan haluttuun muotoon. Valmistusautomaation kehittyessä CNC Press Brakea käytetään yhä enemmän. Niistä CNC-seurantatukitekniikka on tärkeä osa taivutuskoneautomaatiota.

CNC-seurantatukijärjestelmä koostuu kolmesta pääosasta:

1. Paikantunnistusyksikkö: Käytä valosähköisiä antureita tai muita asentoantureita havaitaksesi työkappaleen sijainnin muutoksen reaaliajassa.

2. Servokäyttöyksikkö: Asennontunnistussignaalin mukaan tukilaitetta käyttää servomoottori nopean seurannan saavuttamiseksi.

3. CNC-järjestelmä: Vastaanota sijainnintunnistussignaali, laske tukilaitteen optimaalinen liikerata ja anna ohjausohjeet.

Käytännön sovelluksissa CNC-seurantatukijärjestelmän on sovitettava yhteen Press Brake -järjestelmän CNC-järjestelmän kanssa optimaalisen suorituskyvyn saavuttamiseksi. Tukilaitteen liikerataa tarkasti ohjaamalla se voi varmistaa, että työkappaletta tuetaan aina luotettavasti koko taivutusprosessin ajan, mikä parantaa taivutuksen laatua. CNC-seurantatukea käytetään enimmäkseen pidempien ja leveämpien ohutlevyjen taivutukseen. Se voi tehokkaasti estää metallilevyn muodonmuutosta ja taipumista taivutusprosessin aikana, mikä johtaa epätarkkaan taivutustarkkuuteen.

CNC-seurantatukiteknologian sovellus- ja kehitystrendi

CNC-seurantatukitekniikkaa käytetään laajalti metallin muovausprosessoinnissa sellaisilla teollisuudenaloilla kuin autoteollisuus, kodinkoneiden valmistus ja ilmailu. Industrial 4.0 -aikakauden myötä tämä tekniikka kehittyy edelleen korkeamman älykkyyden ja integraation saavuttamiseksi.

Tulevaisuudessa voimme odottaa CNC-seurantatukijärjestelmällä olevan seuraavat ominaisuudet:

1. Älykkäämpi: käyttämällä konenäköä, tekoälyä ja muita tekniikoita mukautuvan säädön ja vikadiagnoosin saavuttamiseksi.

2. Integroitunut: syvästi integroitu taivutuskoneen pääohjausjärjestelmään, älykkääseen valmistuksen suoritusjärjestelmään jne. prosessin täyden digitalisoinnin saavuttamiseksi.

3. Joustavampi: Tukee erilaisia työkappaleen muotoja ja materiaaleja vastaamaan laajempiin tuotantotarpeisiin.

Lyhyesti sanottuna CNC-seurantatukitekniikka on avain taivutuksen laadun ja tuotannon tehokkuuden parantamiseen. Muihin liittyvien teknologioiden jatkuvan kehittymisen myötä sillä on entistä tärkeämpi rooli tulevaisuuden älykkäässä valmistuksessa.

Suositeltava Tuotteet

Kuumia uutisia

-

Saudi-Arabia-WC67K 100T 3200 NC puristusjarru & QC12K-4x3200 leikkauskone ja 3x3100 taittokone

2024-11-11

-

USA-PANEELI 1400PA3-DA TAIVUTUSKESKUS

2024-10-28

-

Argentina-WC67K 125T 3200 CNC-puristin ja QC12K-4X3200 leikkauskone

2024-10-25

-

Taivutuskeskusten pääkäytöt ja kehitys

2024-10-24

-

Indonesia-WC67K-30T 1600/63T 2500/100T3200/160T 3200 CNC-puristin

2024-10-21

-

Kuinka käsitellä paineen puutetta Press Brakessa

2024-10-15

-

Press Brake:n huoltaminen: 28 vinkkiä pitämään Press Brake täydellisessä kunnossa

2024-10-04

-

Meksiko WC67K 80T 3200 NC puristusjarru ja QC12k-6 × 3200 leikkauskone

2024-09-26

-

Kattava opas taivutusmuovaukseen

2024-09-26

-

Tervetuloa intialaiset asiakkaat käymään tehtaallamme

2024-09-23

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY