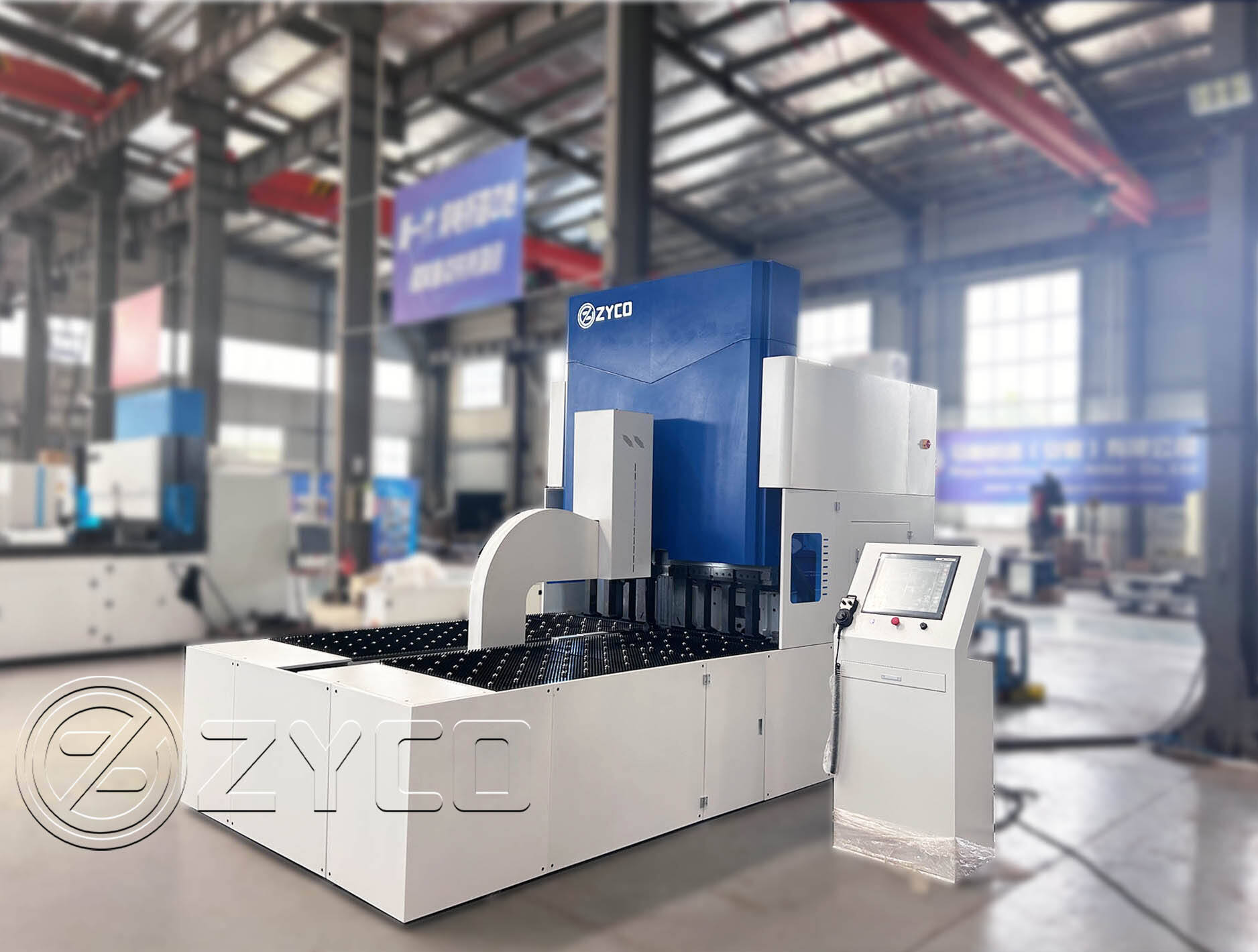

Ever seen a large machine that can mold metal sheets into any shape? It is known as the CNC sheet bending machine. The initials, CNC stand for, computer numerical control. “Which implies, a computer communicates to the machine what needs to be done. This incredible machine can form a variety of shapes from flat metal sheets. While we can make enclosures, signage, and even tooling to create components for other machines in our daily existence.

Role of CNC sheet bending machines:

CNC sheet bending machines are essential for producing a great number of products we use in everyday life. These smoothly shape the sheets according to the design. They are very fast workers and hence spare factories a lot of time as well as money. Do you know how much time it would take to bend metal sheets using the hands? The CNC machine can make this job much faster. Also, because the machine is so specific in performing its tasks; it causes errors to be less frequent and waste to a minimum. This just means the whole process of making things is quicker and allows companies to make better products.

Benefits of a CNC sheet bending machine

The CNC Sheet Bending Machine is able to product the shape with close tolerance from actual designed. The machine is generated to pursue set of design with not much errors like in the case where we use human worker. There could be errors to a human bending metal by hand, this is meant to eliminate those error with the machine. It can also work very quickly unlike man, and least not till date: 2016 Due to never having to take breaks or rest periods it is a very efficient manufacturing tool in comparison with human beings. Also, this machine is flexible in the sense that it can cut a wide variety of metal sheets. It is the reason why they can be applied for all sorts of operations in industries and as such, a useful tool that fits virtually any project you may have.

Mechanism of CNC Sheet Bending Machines:

Now comes the real question how CNC Sheet bending machine work bending metal sheets to specific shapes is achieved by a computerized process. To begin with, a design is made on a computer using software that makes the process sometime like drawing. After the design is made, it is sent to a CNC machine. The hydraulic pressure, which is a strong force, would then bend the metal sheet according to how it should be formed. This allows the machine to stay true to drawing, producing shapes that are accurate and exact – a very crucial factor in making.

What Is Cnc Sheet Bending Machine?

A CNC sheet bending machine consists of many important parts, each working its own unique job. The essential parts are hydraulic monitors and system, back gauge scaling accelerometer/ indicator; Digital punching /dye. The hydraulic system pushes on the metal sheet, bending it to your desired shape. It is an important tool as it positions the metal sheet correctly with respect to which bends need to be made and where. The punch and the die meet up, they then bend to finalize in the metal sheet. These items are interlinked together in such a way that combining them can carve out very fine and accurate forms from flat metal sheets.

All in all, the CNC sheet bending machine is also an extremely important tool used within manufacturing industry. They are well known for their rapid and accurate metal sheet, in the production of countless forms. Everything is managed by a computer rendering the device very efficient and precise. At ZYCO, we have designed advanced Cnc sheet bending machine that will provide your metal sheets accurate bends according to required shapes at high precision. This makes them a great fit for your manufacturing company. When you load up with ZYCO, your other concerns go away because we can guarantee the best machine for manufacturing industry.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY