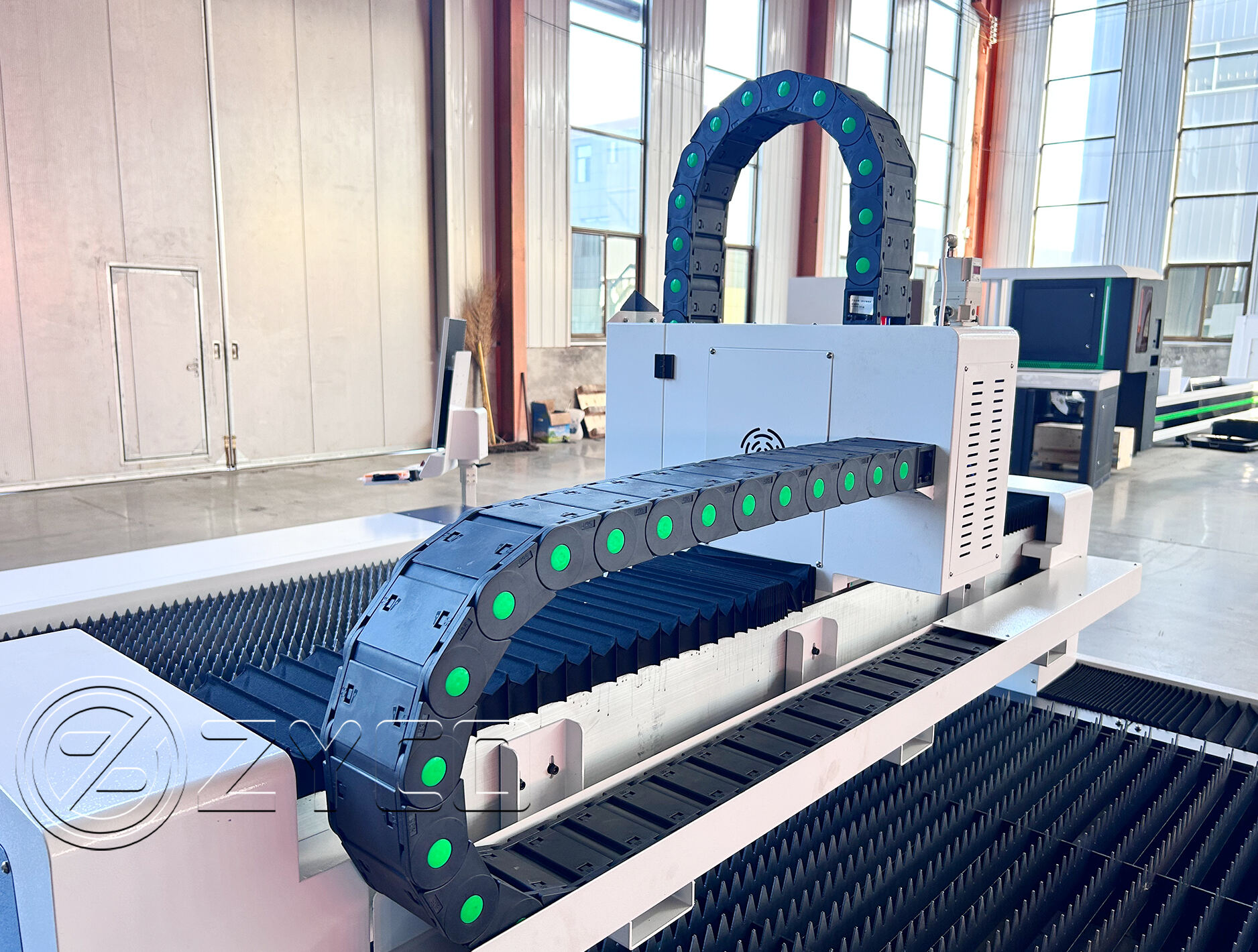

You must be aware of CNC laser cutting machines, right? They look straight out of a movie, but these are real machines that is actually in production today. CNC - Computer Numerical Control: A computer is thus able to help with the management of machinery. Laser cutting is a new technology where by laser rays can easily cut different material in short period of time.

How CNC Laser Cutters Work?

They improve with cutting when discussing cautiousness but quicker as well for CNC laser cutting machines. They can cut all sorts of material from metal to wood or plastic/ fabric. Not only can it generate very intricate designs and shapes, but also cut incredibly precise with its laser. Because the machine is computerized, every cut needs to be meticulous. This would indeed be the saving grace since precision is something that robot can do while humans are not even close to it, especially when you need utmost accuracy on a massive industrial level where slightest of an error could lead to havoc.

Just what Skills Wholesale Used CNC Laser Engraving Cutting Machines Intercept This Labor Market

Small: It is actually possible for CNC laser sawing machinery to slice a wide variety of mediums, and appearance relatively little overall. Car companies have machines which are used to slice a metal part and put in the vehicle. This, in result results in more secure and dependable vehicles. They can design cloth, by cutting and working with fabric to create some beautiful intricate designs in the fashion world capturing clothes or other things. They cut materials for the building of houses as well as various other structures. Such cutting machines can work on an endless number and types of applications.

Until You Learn About CNC Laser Cutting Trends Making Things

CNC machines that have modified partially the way you use in any idea and manufacturing. These are virtually the new, faster and more precise versions of what used to take a lot longer time with less than 100% accuracy. The only difference, of course, is that production occurs more quickly and much less laboriously when using CNC laser cutting machine. That's a win-win for everybody: companies making such high-end goods more affordably, to normal people like us that enjoy new toys.

CNC Laser Cutting Machine Benefits

They are possible with a CNC laser cutting tool that no man ever sees or hears of in the past. For many people, such complex and detailed designs leading to complex shapes can very easily consume a great deal of time by hand if done manually. They also fast in making, and a more economical production for the producer as well all buyers. They are also cost-efficient and hardly waste any materials at all. The fact that you can make more things with less of the material and it is very constructive for our planet, theoretically making this a sustainable solution.

In a nutshell, the CNC laser cutting machines are nothing short of cool that has revolutionized how we create and fabricate. This means that bots are not only accurate, but they have a response time much faster than human and can be used in different use cases by various industries. They benefit everyone since it makes manufacturing faster and more effective. ZYCO manufactures CNC laser cutting machines for businesses that want to start implementing the most precise and versatile manufacturing process in their operations. And — as we hope for CNC laser cutting technology to grow and develop even bigger, somewhere in the world our collective fingers are crossed too that it will all take place on a kinder, greener earth.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY