Types of Grooving machine:

1. Horizontal gantry Grooving machine

2. Vertical Grooving machine

3. Four-side Grooving machine

Structure and performance of Grooving machine:

The Grooving machine base and crossbeam are designed with frame structure, and the work surface is made of low-alloy high-strength structural steel. The overall rigidity of the machine tool is excellent and durable; it is manufactured strictly in accordance with the machine tool processing technology, and electric furnace tempering is used to eliminate welding stress and reduce equipment deformation; sandblasting is used to ensure excellent paint coating effect; the frame is clamped and formed by an imported CNC three-dimensional machining center in one time, ensuring the parallelism and verticality of each installation surface.

The Grooving machine tool holder uses 4 knives to process the "V" groove, so the cutting amount is evenly distributed to reduce the deformation of the workpiece. And an optional micro-cooling system can extend the service life of the tool and reduce production costs; the universal tool clamping mounting surface can meet the clamping requirements of various tools, and the white steel knife and the alloy knife are interchangeable; the tool holder transfer device uses a ground-grade ball screw and a heavy-duty linear guide, so the precision is high.

The crossbeam of the Grooving machine adopts high-precision helical rack and guide transmission with ground helical gears, the moving speed can be adjusted by variable frequency, the double guide structure, and the crossbeam chip feeding process is stable and efficient.

The main uses of the Grooving machine:

The CNC Grooving machine is suitable for industries that require high-precision processing of plates, such as elevators, guillotine materials, stainless steel processing, household appliances, and props display.

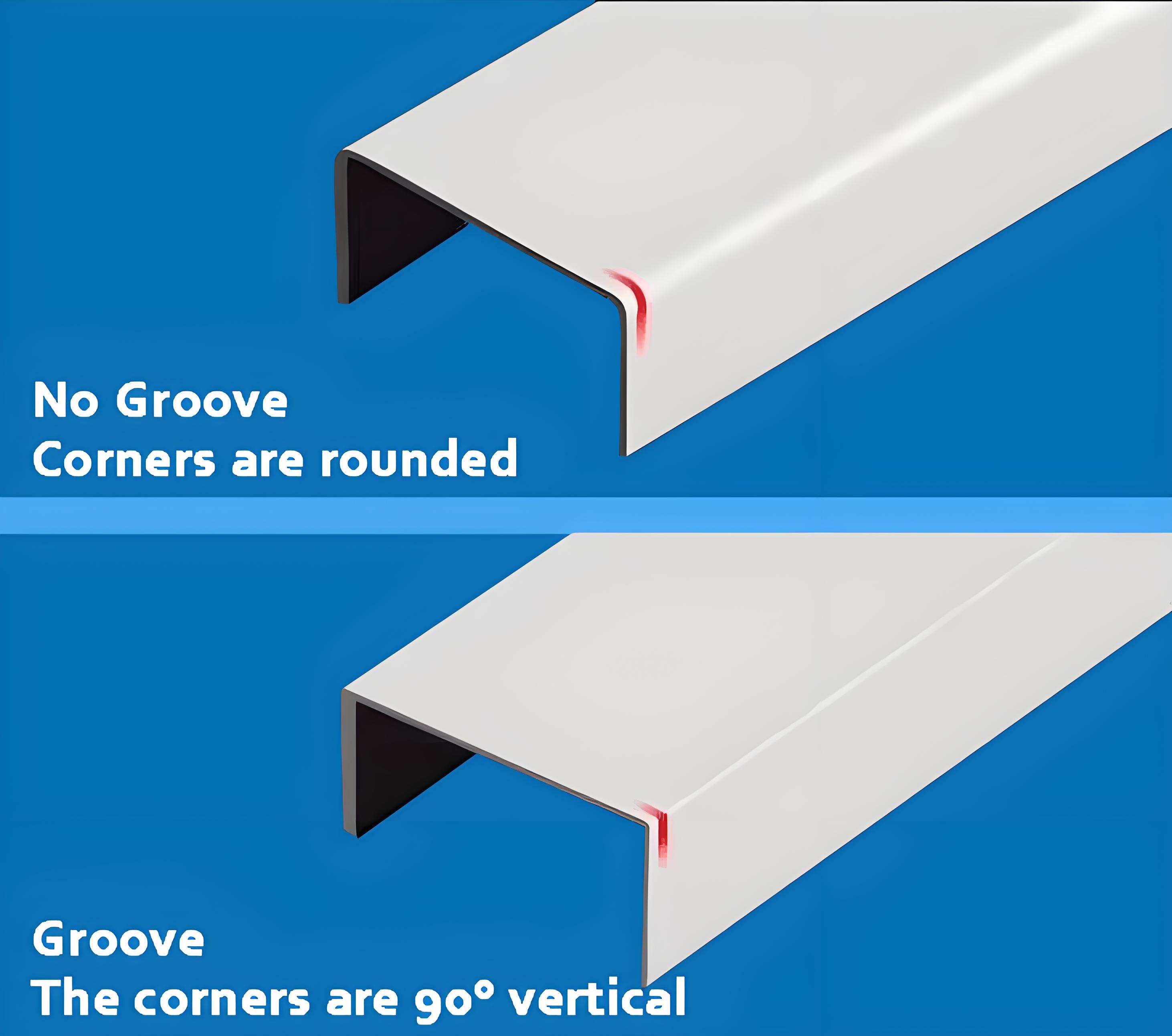

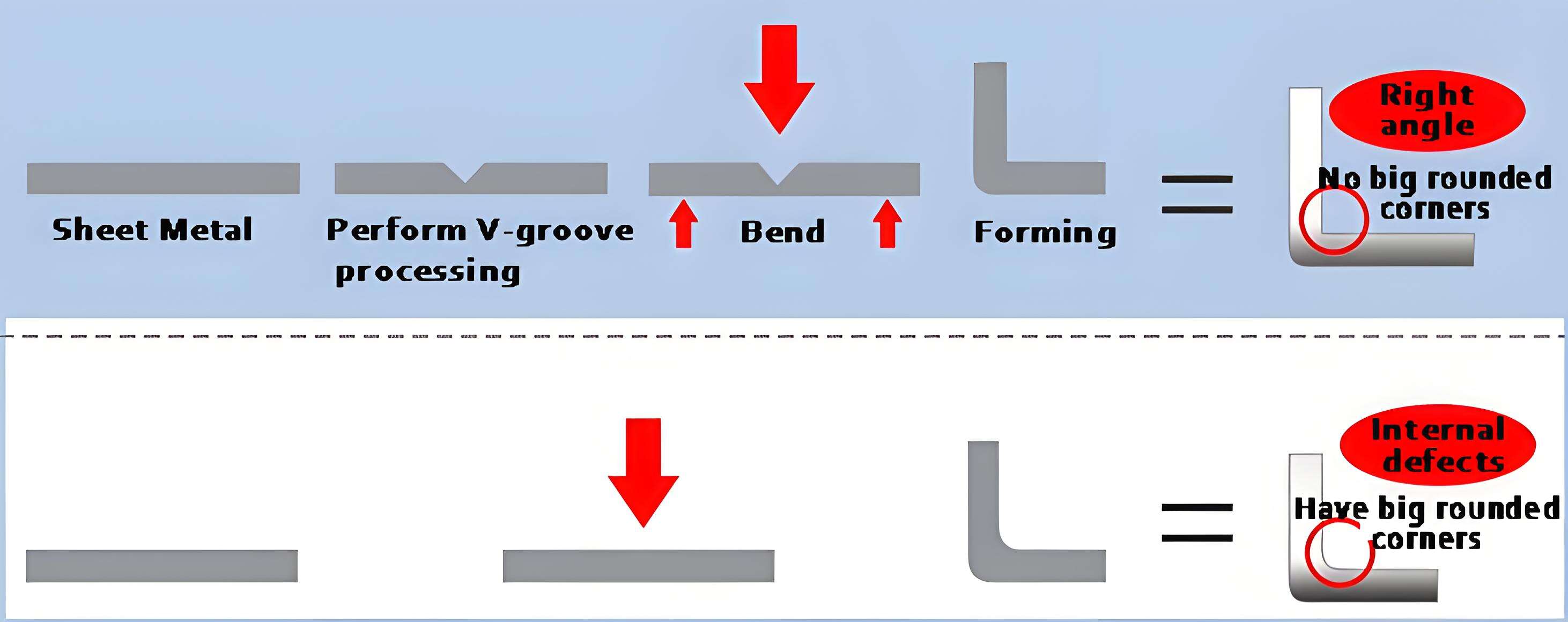

For a series of problems such as large fillets after sheet metal bending and excessive bending rebound, the effect will be significantly improved after the slotting, and the product will be very beautiful and accurate, so it is a machine to assist sheet metal bending.

For some stainless steel processing industries, the planer can also be used directly to cut the sheet metal, because it cuts the sheet metal with the best straightness.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY