With the advent of the Industry 4.0 era and the rapid development of intelligent manufacturing, robots are increasingly used in various industrial fields. Among them, in the field of CNC bending machines, the application of robots is gradually changing the traditional production methods and processes. This article will discuss the application of robots and CNC Press Brake, as well as the advantages and future development trends it brings.

1. Basic concepts of robots in the field of CNC Press Brake

CNC bending machine is a kind of equipment used for bending metal sheets. It controls the movement of molds and workpieces precisely through the control system. A robot is an intelligent device that replaces human labor and can automatically perform tasks. Combining robotics with CNC Press Brake enables a more precise, efficient and flexible production process.

2. Application advantages of robots in the field of CNC Press Brake

(a) Improve production efficiency: The application of robots on CNC Press Brake can realize automated production and greatly improve production efficiency. Robots can perform bending operations quickly and accurately, saving human resources and significantly reducing production cycles.

(b) Reduce personnel risks: Traditional CNC Press Brake operations require workers to operate them themselves, which poses certain safety risks. Robots can replace manual operations, reducing workers' exposure opportunities and reducing the risk of work-related injuries.

(c) Improve product quality: The robot has high-precision motion control and repeatability, which can ensure the consistency and accuracy of each bending operation, thereby improving product quality and consistency.

3. Specific application cases of robots in the field of CNC Press Brake

(a) Automated bending operation: The robot can automatically perform bending operations according to preset programs to complete complex metal sheet bending processing tasks.

(b) Online measurement and calibration: The robot is equipped with sensors and measuring equipment, which can measure and calibrate the workpiece in real time to ensure processing quality.

(c) Flexible production and process optimization: The flexibility of robots allows the production process to be adjusted and optimized according to needs, improving production efficiency and product quality.

4. Movement steps of robot and Press Brake

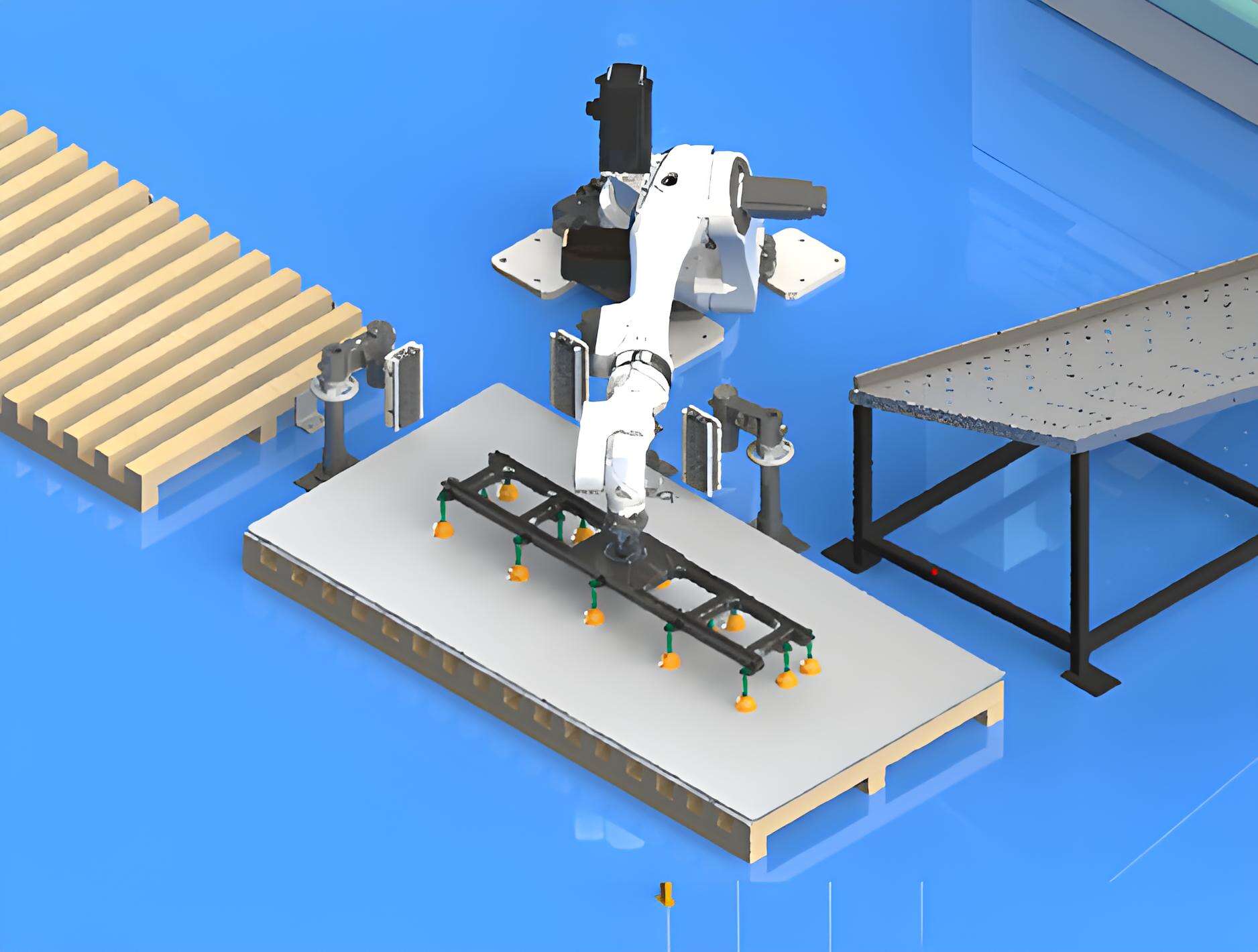

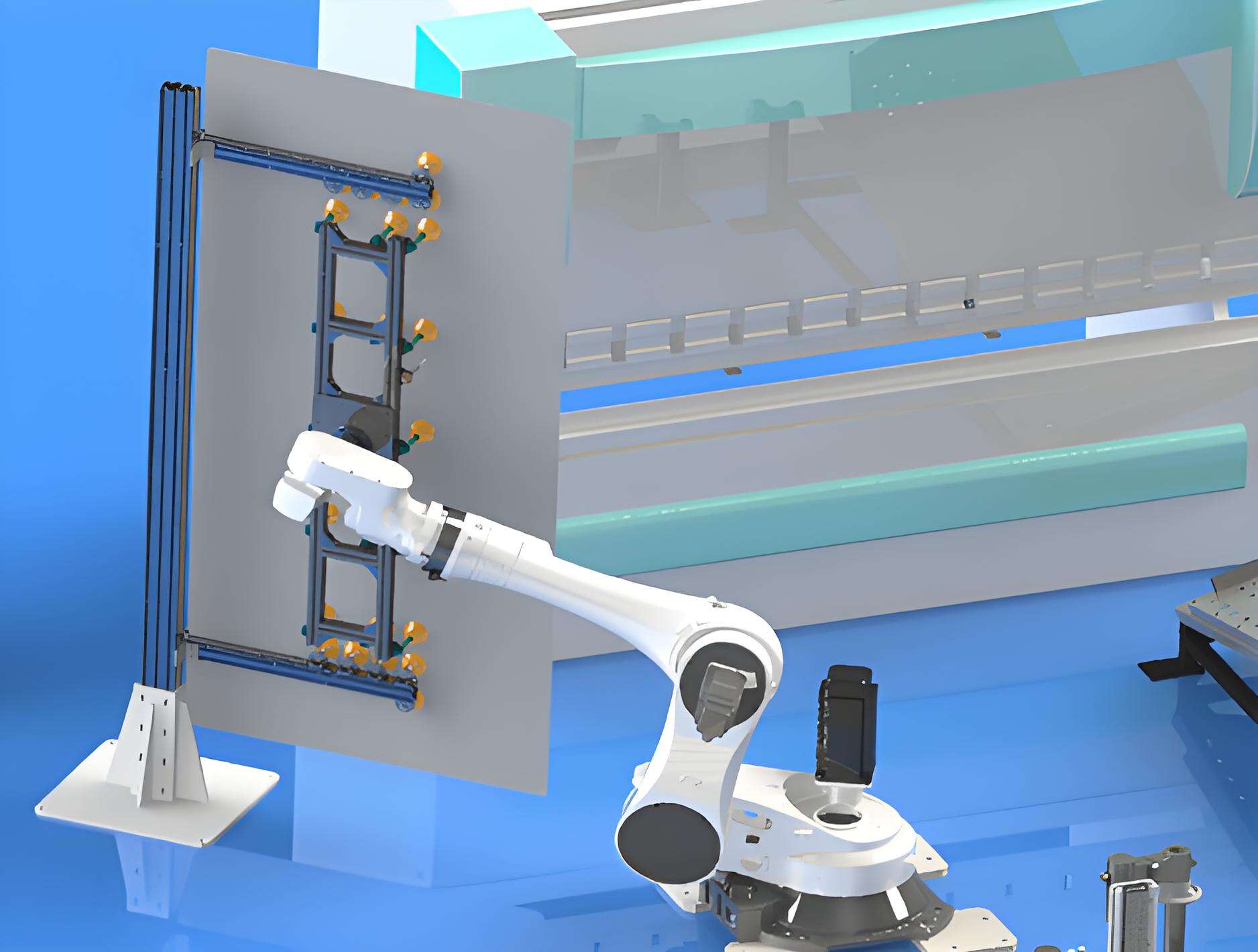

(a)The robot grabs materials from the loading area.

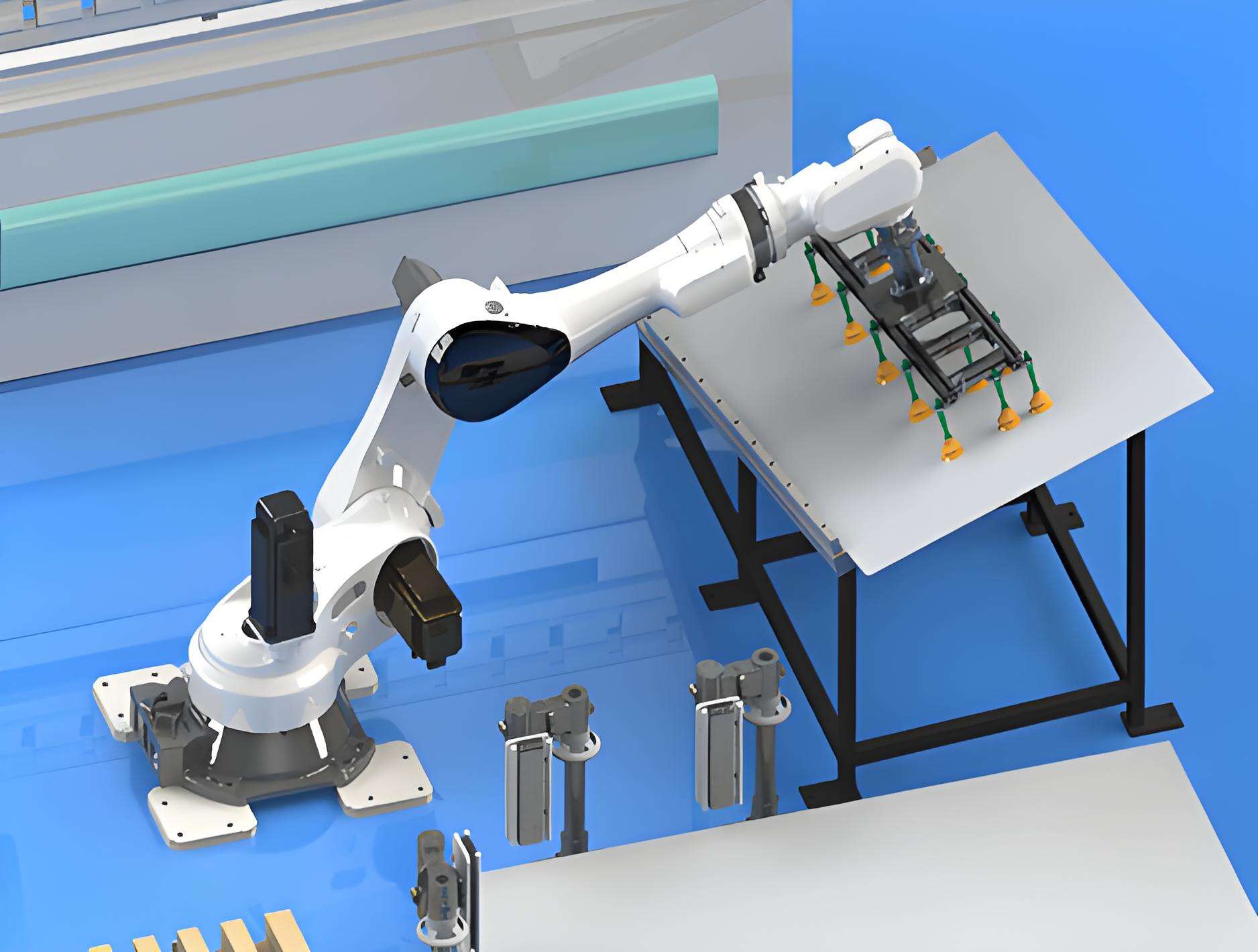

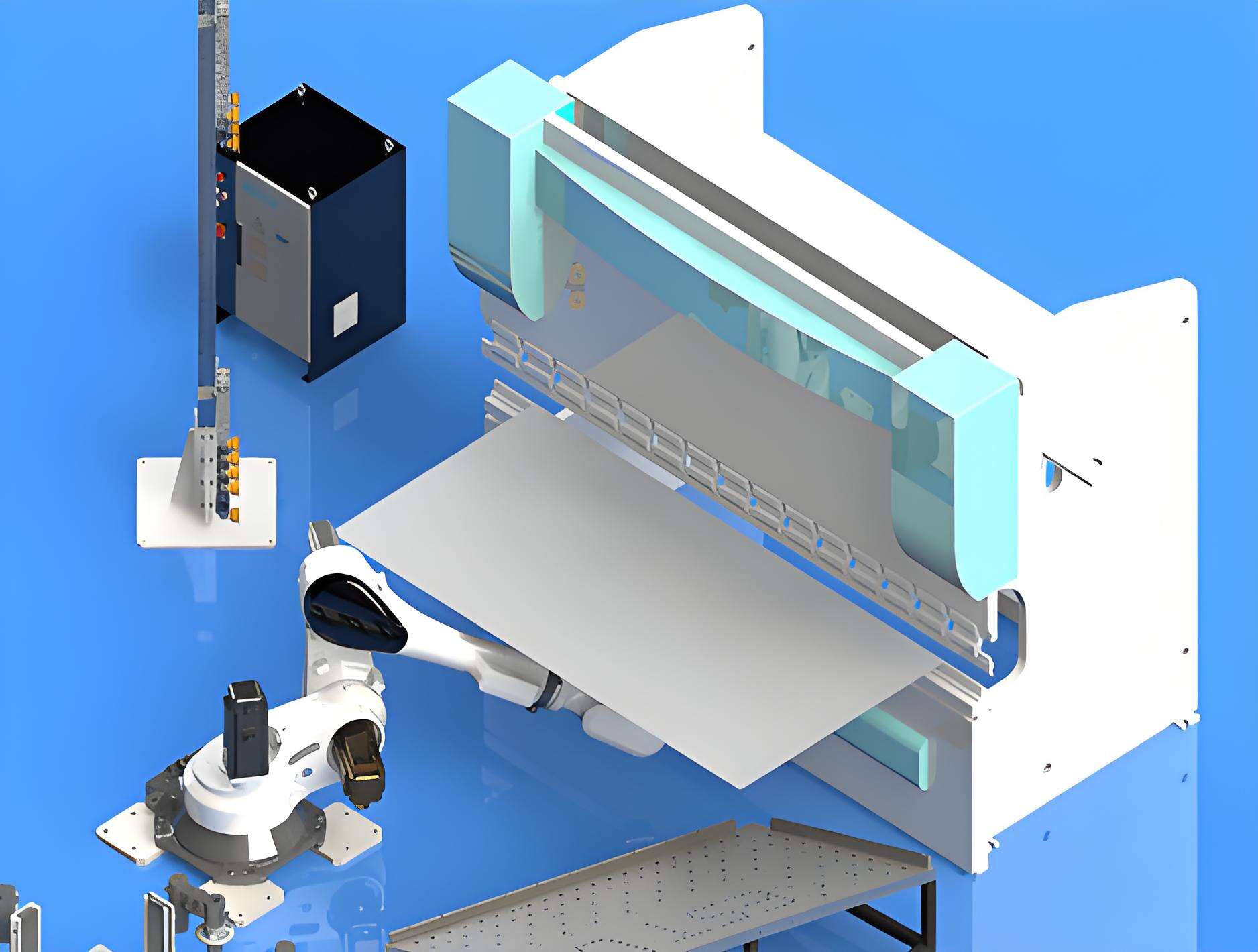

(b)The robot grabs the sheet and places it on the centering table.

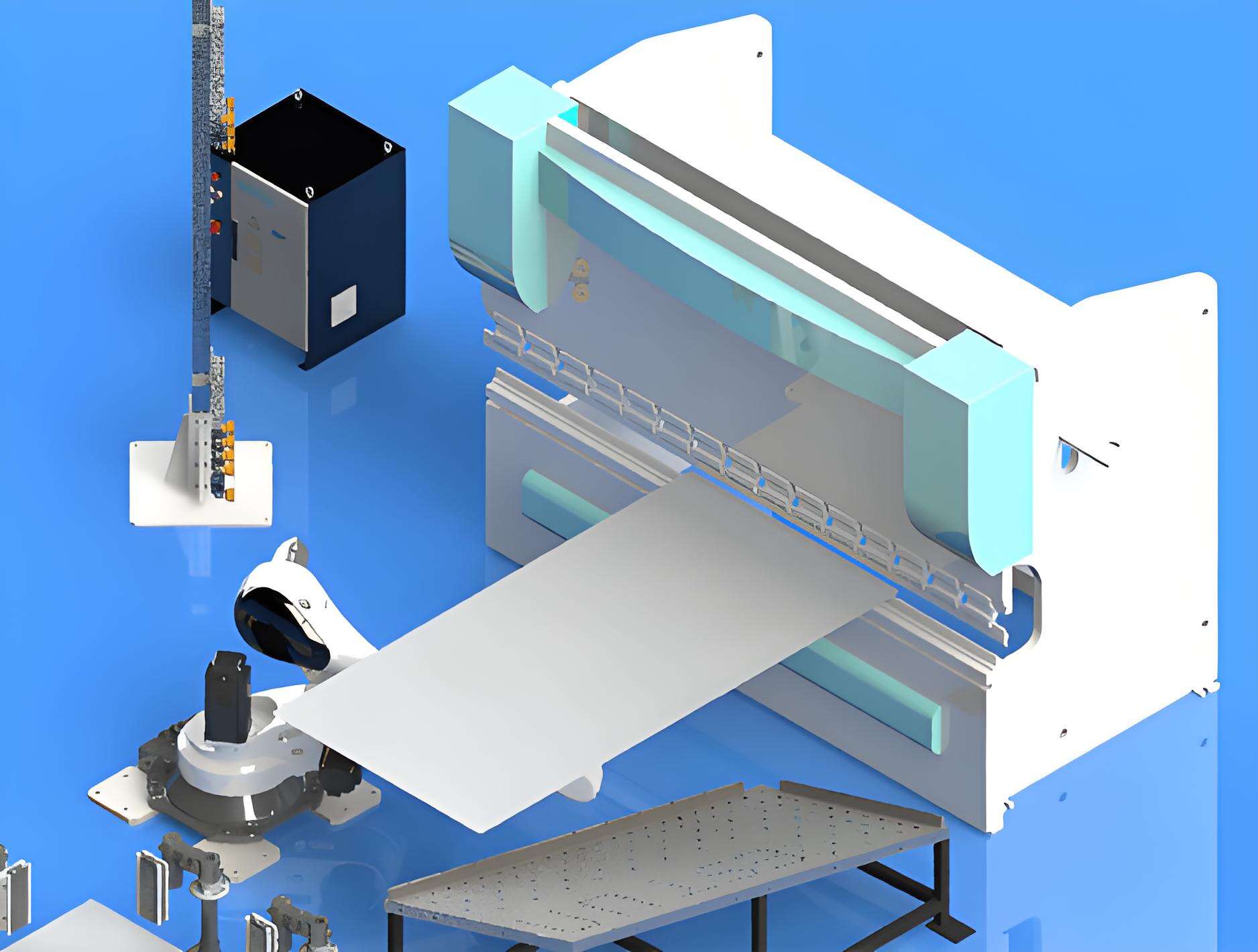

(c)The robot grabs the sheet (short side) and automatically aligns the backgauge system

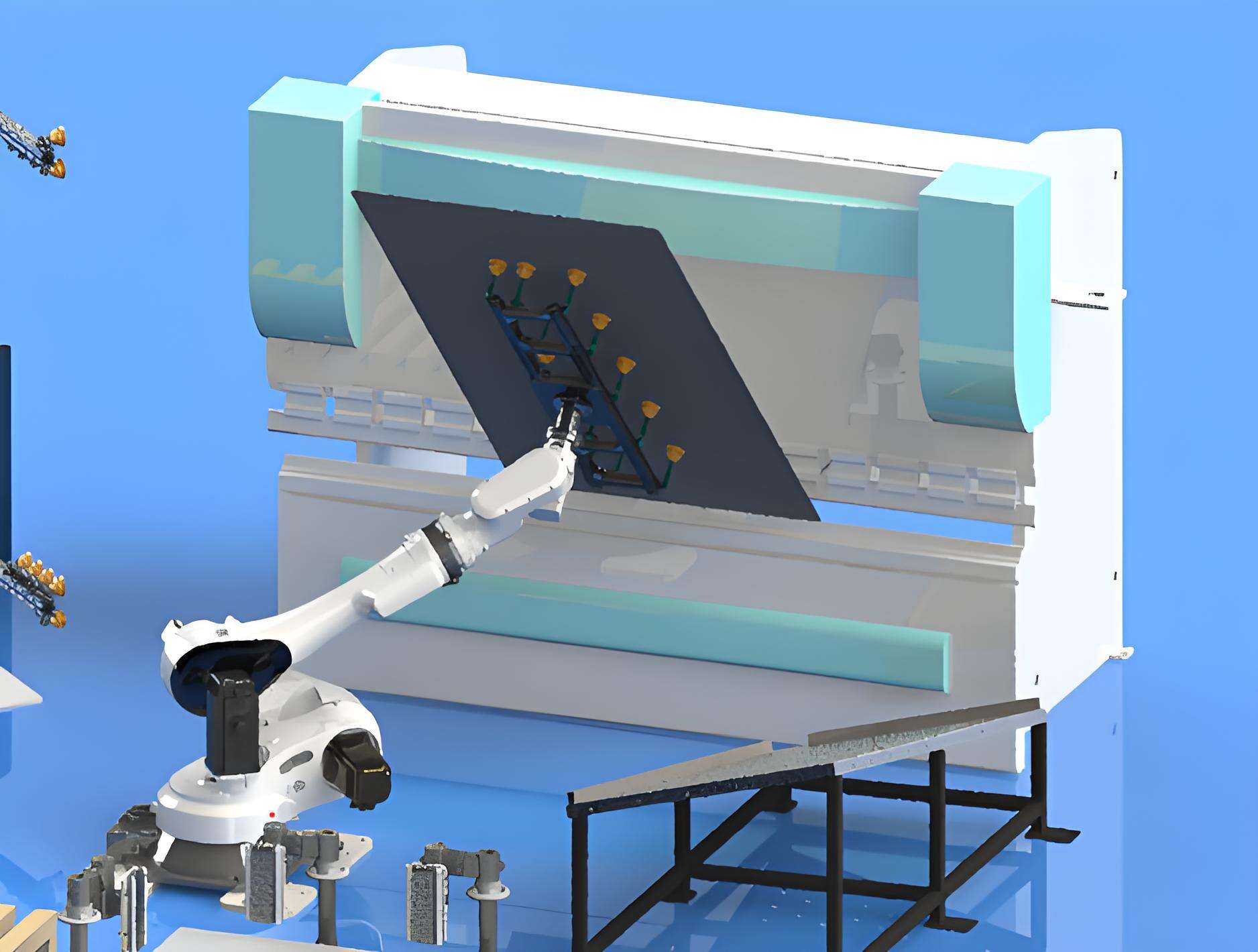

(d)The robot grabs the sheet metal bending machine and follows the bending short edge

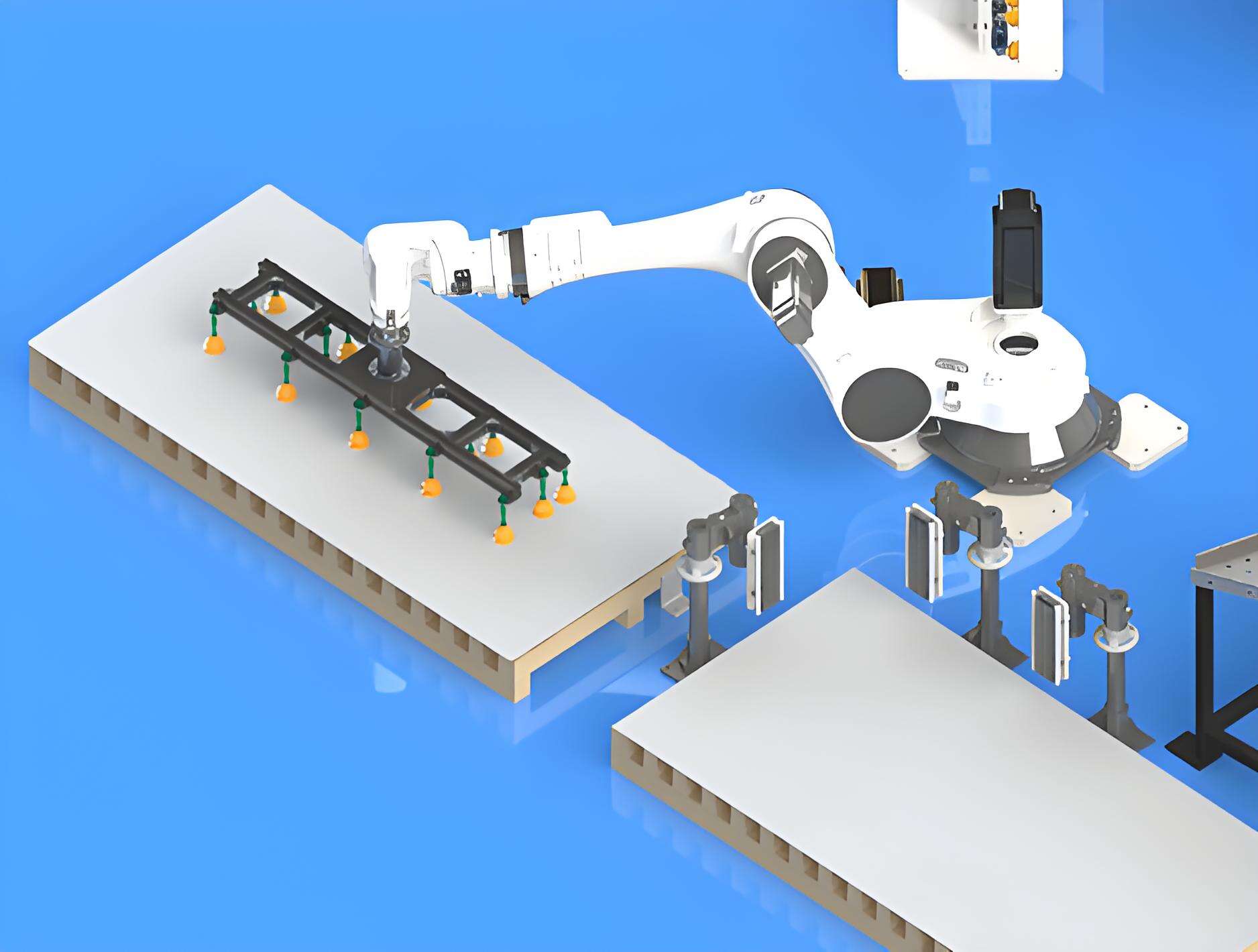

(e)The robot grabs the sheet and uses the turning frame to turn it over

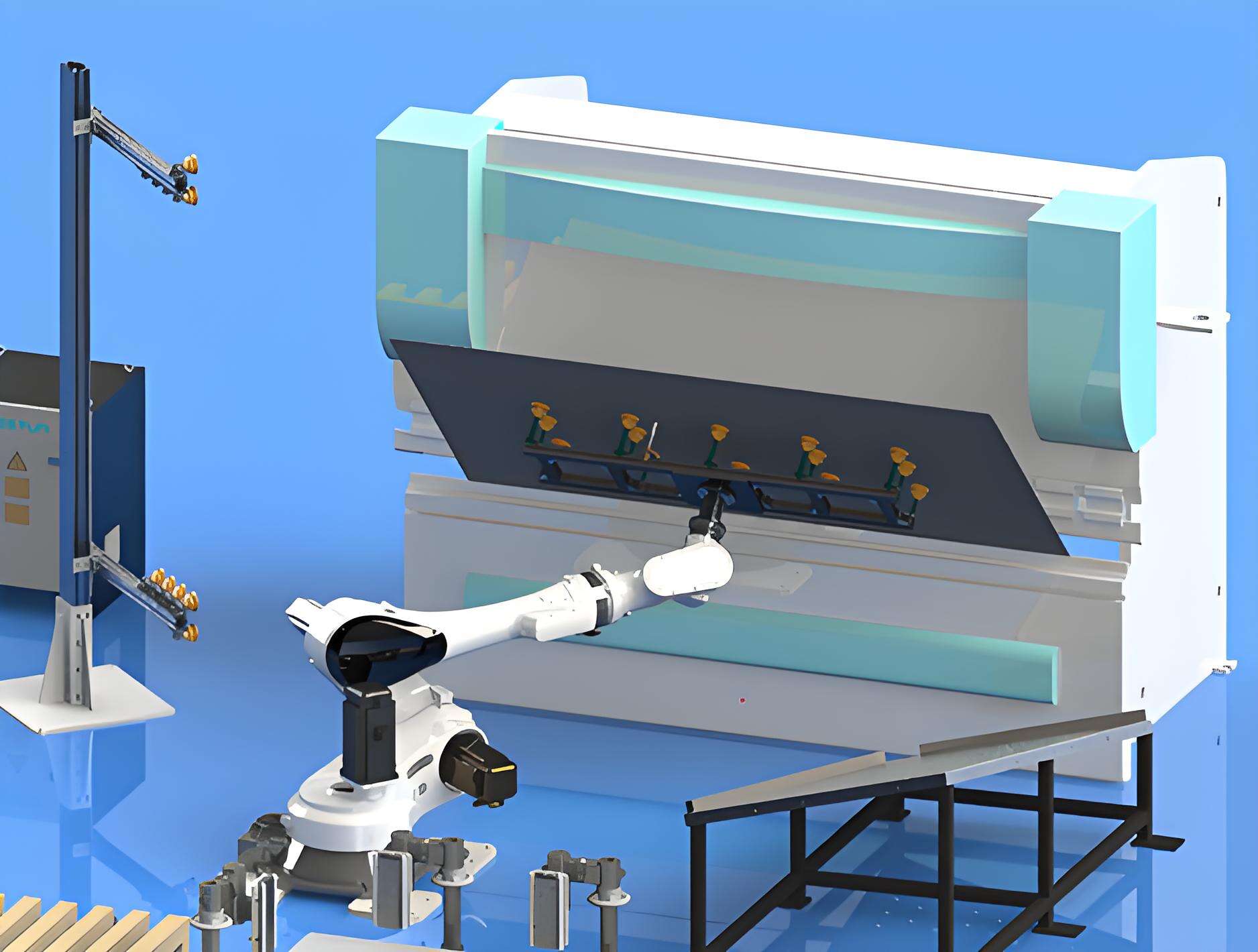

(f)The robot grabs the sheet (long side) and automatically aligns the backgauge system

(g)The robot grabs the sheet metal and the bending machine follows the bending long edge

(h)The robot puts materials into the unloading area.

In conclusion:

The application of robots in the field of CNC Press Brake has brought revolutionary changes to metal sheet processing. It improves production efficiency, product quality and consistency, reduces personnel risks, and brings greater flexibility and optimization space to the production process.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY