The Advantages of Using a Planer for Sheet Metal Bending

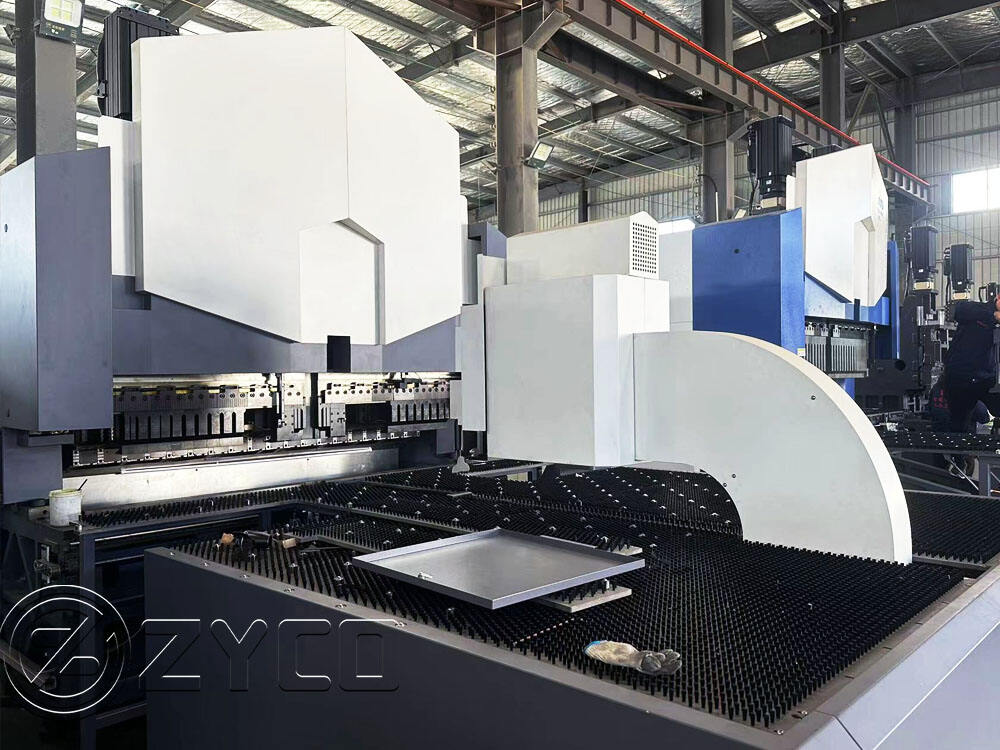

Sheet metal bending a process of shaping sheet metal into different forms and shapes. Then you should consider using a planer if you are looking for a tool can help you with this process. A planer can provide you with a number true for ZYCO sheet metal bending. Firstly, a planer is a tool versatile can be used for a wide range of tasks. It can be used to flatten and smooth out surfaces are rough remove material, and shape and sheet metal bending machine. Secondly, a planer is a tool extremely efficient can help you save effort and time. It allows you to achieve a degree high of precision, which can help you to avoid mistakes are costly. A planer very durable and long-lasting in addition to these advantages. It built to withstand use heavy can withstand the wear and tear of daily use. This makes it a tool ideal any metalworker professional needs to bend sheet metal regularly.

Innovations in Planer Technology

As technology advances, so do the tools we use for sheet metal bending. Planers have come a way long recent years, with many new and innovative features being developed to make them more efficient and effective. One innovation major planer technology the development of computer-controlled planers. These planers use advanced software and sensors to automatically adjust the blade height and speed cutting ensuring each pass optimized for maximum precision and accuracy. This can help to reduce downtime and improve productivity overall. Another innovation in planer technology the use of advanced materials and coatings. Some planers are now made from lightweight yet materials are strong carbon fiber, which can make them more durable and easier to handle. Some planers now feature special coatings can improve their resistance to wear and tear.

Safety Considerations When Using a Planer

While planers are safe to use, it important to take the precautions are necessary avoid accidents and injuries. Always wear appropriate safety gear, including gloves and eye protection, when operating a planer. Be sure to keep your fingers and hands clear of the blade when the planer in use, and never leave the planer unattended while it still running. Planers should always be used in an area well-ventilated avoid inhaling any dust or debris may be generated during the cutting process. Finally, always read and follow the manufacturer's instructions for maintenance and use to ensure your planer operates safely and effectively.

How to Use a Planer for Sheet Metal Bending?

Using a planer for sheet metal bender fairly straightforward, but it does require some practice and skill. To begin, adjust the blade height and speed cutting to the thickness and hardness of the metal you are working with. Next, use the planer to remove any spots are rough imperfections on the surface of the metal. Once the metal has been sufficiently smoothed out, you can begin to shape it using the planer. This done by slowly feeding the metal through the planer, making sure to apply even pressure and maintain a speed consistent. It will be bent and shaped according to the depth and angle of the blade as you feed the metal through the planer. Finally, check your work to ensure the metal has been bent to the desired angle and shape, and make any adjustments are necessary repeating the process until your sheet metal bent to perfection.

Quality Service and Applications of Planers

It important to choose a reputable manufacturer offers excellent customer service and support when it comes to finding a high-quality planer for sheet metal bending machine. Look for a company that has a proven track record of producing reliable, durable planers are designed to meet the needs of professional metalworkers. Once you have found a planer meets your needs, you can begin to explore the applications are many different which it can be used. A planer can help you to achieve speed, efficiency to your goals, and precision, making it an essential tool for any metalworking professional from bending sheet metal for roofing and construction projects to creating custom metalwork for artistic and decorative purposes.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY