Are you thinking about sheet metal bending? Do you require to discover exactly how it is actually performed as well as exactly just what pros it might carry? After that possibilities are actually you handled your appropriate area ought to your reaction is actually indeed. Our team will talk about the idea for the radius of bending of sheet metal, exactly how it is actually place, as well as what their benefits are actually.

What is the Radius of Bending of Sheet Metal?

The radius of bending of sheet metal associates to your very little indoor bending that the level sheet of metal may be curved right in to without breaking or even damaging. This radius depends on the material's deepness, its own modulus of flexibility, as well as various other elements. The radius of bending machine is actually essential for anticipating the sheet metal's formability as well as is actually an essential specification designers which style sheet metal items.

Benefits of Sheet Metal Bending

Sheet metal bending has actually a lot of benefits. The main benefit which it might creating complicated as well as precise types is actually certainly not carried out in addition to various other techniques. This flexibility allows sheet metal to end up being discovered in lots of items, coming from home devices to vehicles as well as airplane. Bending furthermore reduces the value when it happens to completed product getting rid of the requirement for several components, which might top to cost financial savings. Likewise, sheet metal bending machine can easily create models that might be inexpensive screening, creating it feasible for fast product establishing.

Innovation in Sheet Metal Bending

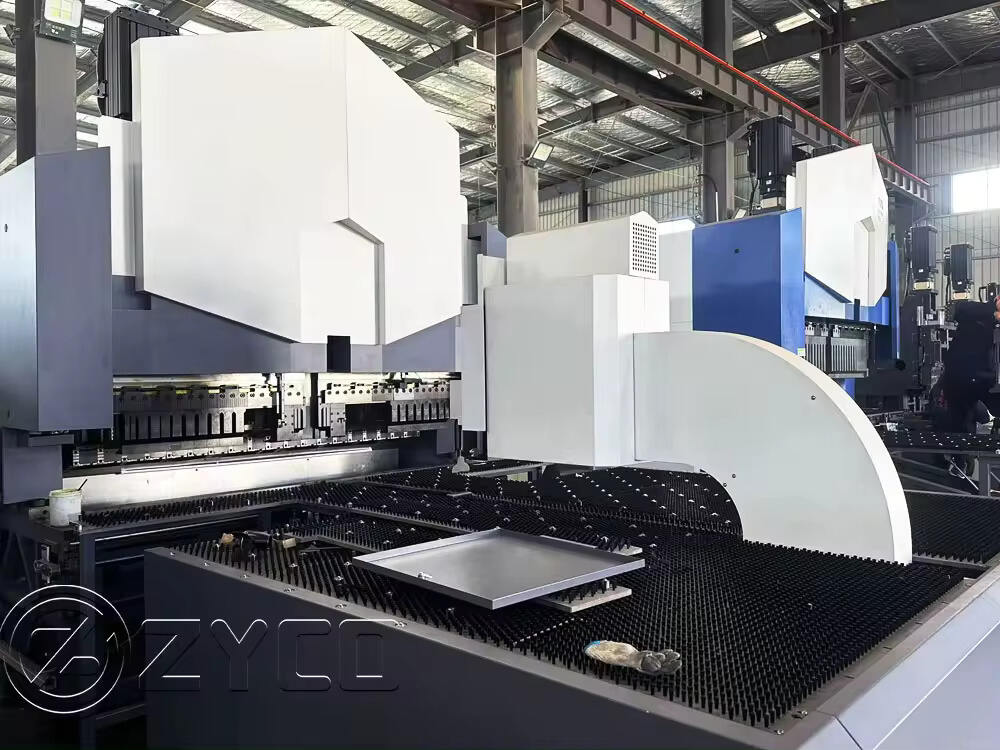

Advancement in sheet metal bending has actually produced the establishing of more recent methods which enhance the price as well as precision connected with the procedure. One specific development using computer system numerical command (CNC) devices, that utilize computer system courses to exactly command the bending technique. Another brand-brand new method using laser device reducing, which enables elaborate as well as precise reduces be actually specified in the metal. These developments have actually allowed service companies to assist create much a lot extra complicated as well as higher-quality items the quicker price.

Security Factors to consider in Sheet Metal Bending

Security is actually an essential issue when utilizing sheet metal bending devices. To guarantee much more secure treatment, drivers ought to feel qualified thoroughly to determine as well as prevent risks, like vigorous edges squeeze standards, as well as taking a trip particle. Eye as well as ear security likewise crucial, when appertains air stream as well as breathing security whenever utilizing harmful chemicals. Complying with security procedures certainly not simply assurances the continuous physical health and fitness and also wellbeing of employees, however additionally decreases the opportunity of issues for steel bending device as well as the sheet metal.

How to Utilize Sheet Metal Bending?

Sheet metal bending is actually a specific treatment needs specific devices understanding. To flex sheet metal, it should very initial be actually reduce in the direction of the suitable measurements type. The metal is actually after that set up into a device bending brake that secures as well as folds the metal in to the preferred form. The brake's clamp maintains tension on the metal, as well as the driver gradually applies pressure flex the metal prior to the defined form is actually accomplished. The job are actually duplicated numerous opportunities concerning the last type achieved.

Quality Guarantee and Application

Quality control is actually important in sheet metal bending to ensure which the finished product their meant request as well as specifications. It offers looking for defects like fractures or even damages which will certainly concession the item's stability. Producers such as ZYCO likewise utilize different examinations to inspect the metal's firmness, ductility, as well as durability to make sure it satisfies market requirements. After the metal is actually considered much more secure as well as of shut high top premium, it may be used in choice of requests, coming from frameworks as well as enclosures to equipment as well as devices.

EN

EN

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BE

BE

HY

HY

KA

KA

UR

UR

BN

BN

MN

MN

KK

KK

SU

SU

TG

TG

UZ

UZ

KU

KU

KY

KY